Accuracy of Thermocouple Tubes Without Calibration

Unexpected sensor failures, breakage and contamination happens to all of us. Hopefully you have a spare on hand when a sensor breaks in the field. You quickly switch out your vacuum tubes and proceed without hesitation. Unfortunately it’s rarely that easy – there are small electrical differences between each sensor; thus, your backup sensors will produce different readings on different vacuum gauges without calibration.

Unfortunately, factory recalibration isn’t always an option at the time. This should raise some logical questions with technicians; how reliable and accurate are the readings produced by backup vacuum tubes? We set out to answer this question by performing an experiment in the DigiVac shop.

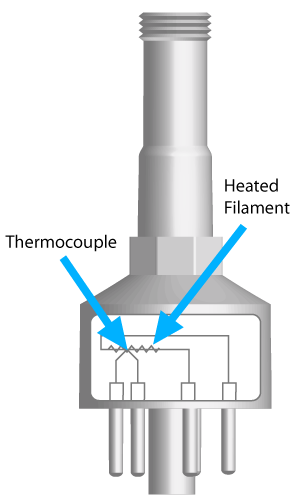

At DigiVac, each vacuum gauge is calibrated to a specific sensor in order to compensate for varying resistance levels produced by the wires in a thermocouple sensor. This is why most manufacturers recommend calibration after switching tubes or on a yearly basis. Learn how thermocouple sensors work or how to clean them here.

Experiment Goals:

- Investigate how each vacuum gauge performs with a sensor to which it was not calibrated

- Determine what kind of data can be expected (as well as a trend, if any, in the data), if a tube is switched without recalibrating the unit.

The Process:

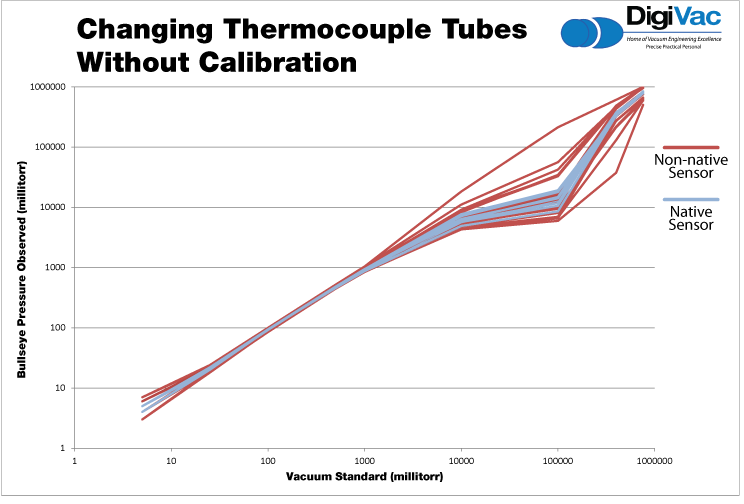

We began with five Bullseye Precision Gauges from stock, labeling each gauge and its assigned sensor. To start, we recorded data with each unit and its originally assigned tube (blue lines on graph) by pumping our vacuum manifold down to 5 microns, allowing readings to settle, and recording readings at test points ranging from 5 millitorr all the way to 760 Torr. Then we removed the sensor cables from the sensors assigned to individual units and swapped – gauge 1 was paired with tube 2, gauge 2 paired with tube 3, etc – until each gauge had been tested with each of the 5 TC gauges. As a final test we re-paired each gauge with its original tube, and recorded a final set of data

Our Results:

Keep in mind that the Bullseye Precision Gauge can claim accuracy within +/- 2 millitorr from hard vacuum to 100 millitorr, 20% of reading from 100 millitorr up to 10 Torr, and 20% of reading from 300 Torr to 800 Torr. The following graph depicts the deviation of vacuum gauge readings when using a non-stock and uncalibrated thermocouple tube.

Between 25millitorr and 1Torr, readings were comparable to those taken with the original tubes, and most observed readings were well within the specified parameters of +/-20% of reading. Offsets from nominal ranged anywhere from 4% below to 28% above, with instances of offsets over 20% numbered only 5 out of 100 individual readings.

Even more cooperative were the readings closer to 10 -3, where the 5 micron reading never differed by more than 2 microns in either direction.

Differences from nominal ranged from 8% to a whopping 90% at the 400 Torr test point. In four cases the readings were not measurable indicating sensor readings above 999 torr. Note, initial readings with the unit’s own tubes showed much more modest variances, all comfortably within the +/-20% range. This suggests that gauge accuracy is highly sensor-dependent at this lower pressure range.

Conclusion:

All data considered, I can conclude that certain pressure ranges are more adaptable to random tubes than others. The efficiency of any given tube for your personal vacuum purposes cannot be guaranteed and will highly depend on your desired pressure range.

Will an emergency replacement tube make the grade for you? This depends on two factors; namely, the pressure range that is relevant to your work, and the need (or lack of need) for pinpoint accuracy in your pressurized system.

In emergency situations, field calibration can be attempted, but is not recommended. There are instructions for included in the user’s manual; however, for optimal results, the unit must be calibrated both under a pressurized system, and against a standard whose readings you trust. An intermediate step you might consider is calibrating only the atomospheric pressure (760 Torr) since this is the region most susceptible to tube swapping. Another option is to consider digitally calibrated tubes, which will be the topic of a future technical note.