Description

Ai SolventVap 2L Rotary Evaporator | Chiller & Pump 110V

Product Description

- (PN): SE05-C15-DTC41

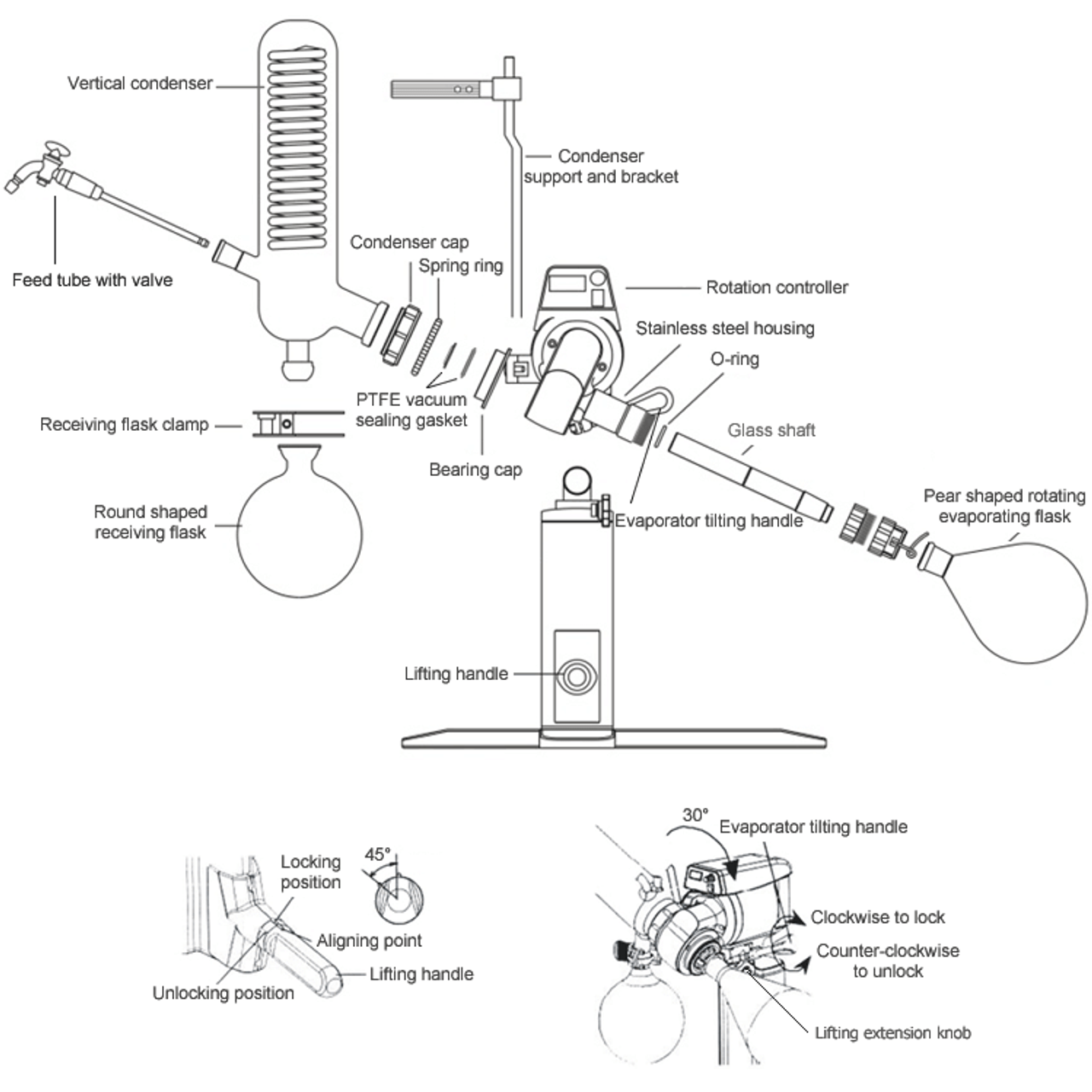

Ai SolventVap 2L (evaporating flask capacity) series rotary evaporators come with a modular heating bath, vertical glassware, and digital temperature/rotation control. Its optimized bath volume allows for rapid heat-up times. The condenser unit has specially designed glass tubes that utilize surface area extremely efficiently. Thats why Ai SolventVap evaporators consistently deliver reliable and reproducible process results that are usually reserved for more costly systems. Another important aspect of the SolventVap is the safety features, which includes dry-run protection, water bath over-temperature shut-off protection, and fuse protection.

SolventVap evaporators consistently deliver reliable and reproducible process results that are usually reserved for more costly systems.

Features

- ETL tested to UL and CSA standards

- New electric evaporator flask lift, nonexposed water bath heater, and plexiglass bath cover, standard

- Solvent-resistant PTFE and Viton gaskets ensuring long time operation.

- Specialized motor with extremely compact, intermeshed worm and worm gear provides precise driving for very quiet, vibration-free operation.

- Downward-condensing vacuum connection design ensures safe vacuum operation.

- Modular design (individual rotary and water bath modules) for easy future upgrades.

- Easy multi-level manual lift with secure lock for the evaporating flask.

- Easy, straight-forward visual operation with digital speed and temperature display.

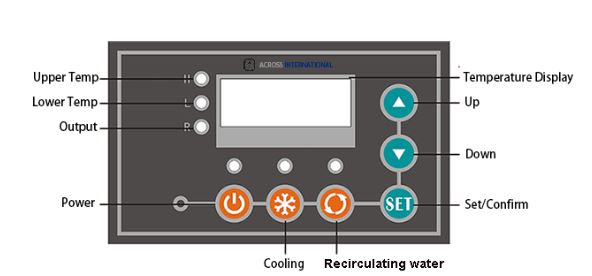

- PID temperature controller ensures accurate temperature control is maintained.

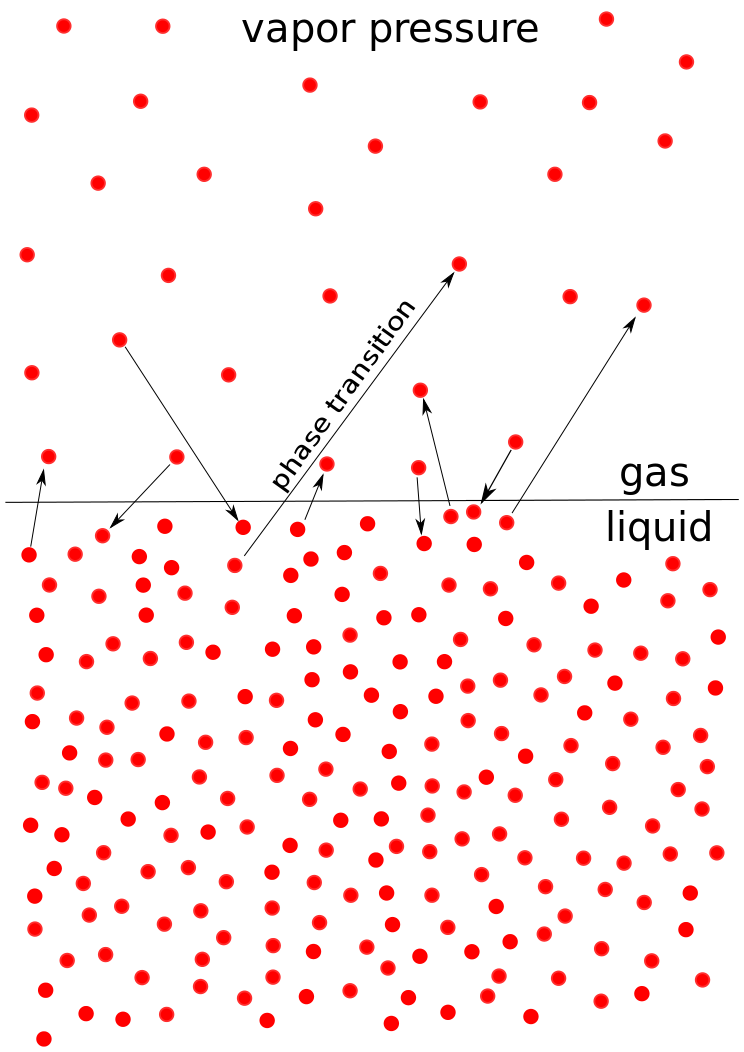

DigiVac’s Vapor Pressure Controller (VPC)

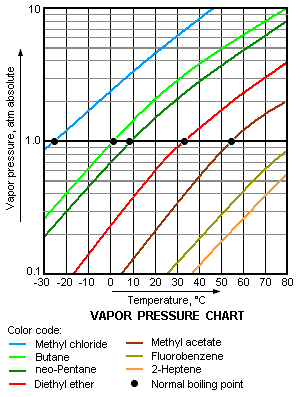

The DigiVac Vapor Pressure Controller allows you to determine set-points and maintain vacuum at that level. The vacuum regulator is particularly useful when you are looking to maintain pressure at a certain level as needed for botanical processing and rotary evaporation or ideal for any vacuum process that involves vapors. Mounting can be bench-top or on a laboratory pole.

- Display of both the set-point and current vacuum control

- Fine control of target vapor pressure for more precise compound separation through distillation

- Flow path designed to be tolerant of harsh chemicals

- UL, CE, CSA and RoHS Certified, Fully safety certified for USA, Canada and Europe

For more information + downloads, click here.

Technical Specifications

| Electrical requirements |

110V 60Hz 1~phase, 1,340 watts (heater: 1,300 watts, rotation motor: 40 watts) |

| Glass material | High borosilicate glass 3.3 |

| Evaporating flask | Capacity: 0.13 gallon (0.5L), 0.26 gallon (1L) or 0.53 gallon (2L) Maximum load: Not to exceed 60% of the flask’s capacity Rotation speed: 10 to 280 rpm Evaporating speed: 20 ml per minute Lifting: weight balancing manual control with lock Max lifting distance: 4 inches (extendable to 10 inches) |

| Receiving flask |

0.26 gallon (1L) |

| Condenser | Glassware: Vertical with dual-spiral glass tubing Chilling fluid connection: 3/8″ hose barb x 2 Vacuum connection: 3/8″ hose barb x 1 Condensing surface: 1,260 cm2 or 1.4 sq ft |

| Working environment | 5 to 95F |

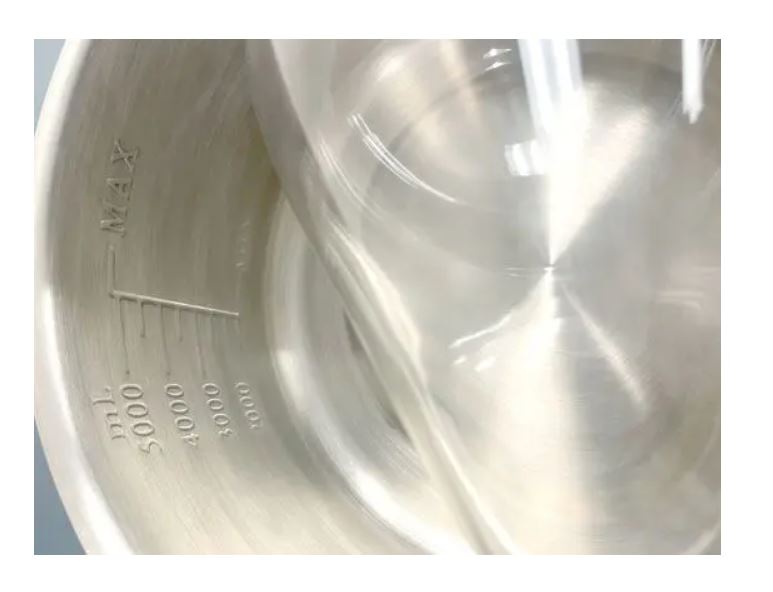

| Water bath |

Temperature range: ambient to 95C Temperature controller: digital Capacity: 6.5 L Material: stainless steel Dimensions: 10″ diameter x 5″ depth x 9.75″ height Media: distilled water only Max. water level: not to exceed 1″ from the top rim of the bath Number of heaters: one |

| Vacuum | Connection: 3/8″ hose barb x 1 (on condenser) Sealing: PTFE + Viton gaskets Ultimate vacuum: < 3 torrs |

| Safety | Dry-run, over-temp shut-off, fuse protections |

| Weight & dimensions | Unit vs shipping: Rotary evaporator: 21 / 40 Lb Rotary evaporator: 22 x 12.5 x 26″ / 26 x 21 x 29″ (WxDxH) |

| Warranty | One year warranty on rotary evaporator except glassware and all sealing gaskets. Glassware may have minute blemishes that will not affect the function. If you believe there are imperfections on your glassware, please contact us. We check all our inventory and make sure no defective glassware is sent to our customers. |

| Download | Ai rotary evaporator brochure |

| Compliance | ETL tested to UL and CSA standards |

Pump Curves

Ai SolventVap 2L SE05-S2 Rotary Evaporator Standard Package Includes:

SE05-S2 Standard Package

| Part description | Qty |

Part image |

| Evaporator body with electric flask lift | 1 pc | |

| Water bath | 1 pc |  |

| Vapor filtering bottle | 1 pc | |

| Vertical condenser with 2 chilling water ports and 1 vacuum port, glass |

1 pc | |

| 2L pear shaped evaporating flask, glass (choose based on volume of material to load) |

1 pc |  |

| 0.26G/1L round shaped receiving flask, glass | 1 pc | |

| Glass vapor duct with seal | 1 set | |

| Glass material feeding tube with valve & PTFE extension hose | 2 pcs |

|

| PTFE vacuum sealing kit | 1 set |  |

| Condenser cap kit | 2 pcs |  |

| Glass shaft cap and evaporator flask quick-release | 2 pcs |  |

| Condenser support and bracket | 1 pc |  |

| Condenser support securing screw | 1 pc |  |

| Receiving flask ball joint clamp | 1 pc |  |

| GL14 connector | 3 pcs |  |

| 3-prong 110V US power cord for evaporator | 1 pc | |

| Silicone vacuum tubing | 10 ft | |

| Mechanical vacuum gauge | 1 pc | |

| Ai plexiglass water bath cover for 2L SolventVap | 1 pc |  |

| Users manual | 2 pcs |  |

C15 Package

DTC-41 Package

| ULVAC DTC-41 1.6 cfm full chemical-resistant oil-free diaphragm pump | 1 pc |  |

| White premium food grade silicone vacuum hose (3 ft) | 1 pc |  |

| Power Cord with plug (may be hardwired to unit or with a detachable plug) | 1 pc |  |

| Threaded Hose Barb (ID: 6mm OD: 9mm) with O-Ring (CS: 2.5 mm ID: 10 mm) (May be Installed on the unit) | 4 pc |  |

DigiVac Recommendations

Vacuum Control: VPC with VPPM Software for running recipes or RAMP control or the SNAP Vacuum Controller with onboard Automatic Process Control and Recipe Control to support SOP development and optimized vacuum drying.

Downloads

For more documentation, please visit DigiVac’s folder.

.gif)