Description

Pfeiffer HiScroll 6 Scroll pump | PD S20 000

HiScroll 6, Scroll pump, standard, including ATEX

Description

Scroll pump 3.6 CFM with gas ballast

- Pn: PD S10 000

Pfeiffer Vacuum HiScroll 6 Oil-Free Dry Scroll Vacuum Pump, 100-240 VAC, 3.6 cfm, KF-25 Inlet & Outlet.

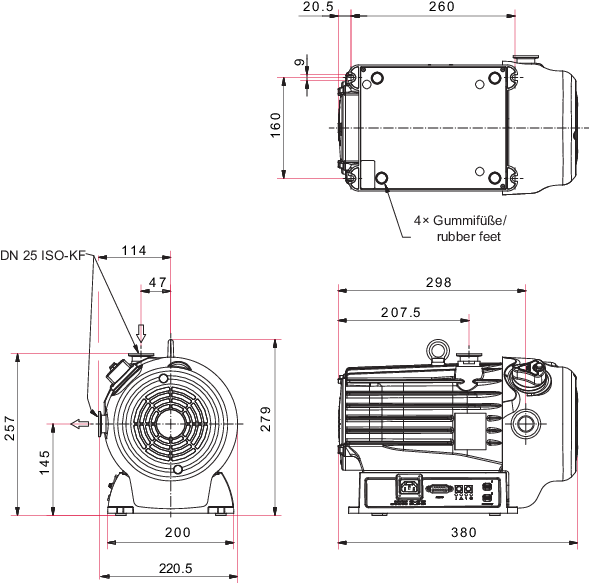

This Pfeiffer HiScroll 6 dry scroll roughing/backing pump has a pumping speed of 3.6 cfm (6.1 m3/hr), and an ultimate vacuum of 1.5 x 10-2 Torr (2 x 10-2 mbar). It has KF-25 (NW25) inlet and outlet ports. Input of 100-240 VAC, 50/60 Hz, single phase power is required and and the pump has a standard C14 input power connector. The HiScroll 6 pump draws 4A@120VAC (2A@240 VAC) and is extremely quiet at 48 dB(A). This HiScroll pump has internal motor protection and an integrated two-stage gas ballast which allows for pumping of condensable vapours including water, solvents, dilute acids and bases. Maximum dry air or inert gas ballast pressure is 21.7 psi (1500 hPa).

The pump has an onboard inverter controller which allows the pump to be controlled either manually with easy-to-use push buttons, or remotely via RS485 when connected to a Pfeiffer DCU or OmniControl controller, or a user supplied software interface. The pump controller has a standby mode and when active reduces the speed of the pump to 50% of full speed to save wear and tear on tip seals and to increase bearing service life. This Pfeiffer HiScroll 6 dry scroll pump has part number PD S10 000.

Pump Features

- No hydrocarbons: Completely dry & oil-free Scroll vacuum pump

- Low noise level, minimal vibrations and compact design, ideal also for use in laboratories

- Safe operation due to the installed non-return valve and hermetically sealed pumping system

- Low operating costs thanks to the highest quality, short maintenance times and long maintenance intervals

- Power as required: Stable pumping speed and short cycle times

- Sustainable: 15% higher efficiency of the drive system, reduced heat generation and minimum cooling requirements

- Industry 4.0 compatible: Operation with other intelligent products, such as turbopumps via RS-485

- Simple logistics: Pfeiffer HiScroll pumps are suitable for all voltages worldwide

Please note: cable has to be ordered as accessory separately

Lowest Noise Emission on the Market: The pumps are also characterized by their very compact design and extremely quiet and low-vibration operation. Therefore, they are ideal for use in quiet working environments, for example on mass spectrometers, research & development institutes or leak detection systems.

Intelligent Control: The Pfeiffer HiScroll dry scroll vacuum pumps can be easily connected to other Pfeiffer Vacuum products (such as turbopumps or display and control units) as well as to a higher-level external controller, via RS-485 or ProfiNet. The interface enables RPM regulation, situation-specific control of the fan and monitoring of the pump performance. This helps to minimize wear and noise emissions, and ensures longer maintenance intervals.

High Safety at Lower Costs: The integrated two-stage gas ballast and safety valve ensure process-specific and safe operation. The proven quality of Pfeiffer Vacuum components guarantees the long lifetime. Easy maintenance of the pumps enables short service times and the efficient motor helps to reduce electricity costs.

The pumps are also characterized by their very compact design and extremely quiet and low-vibration operation. Therefore, they are ideal for use in quiet working environments, for example on mass spectrometers, research & development institutes or leak detection systems.

The Pfeiffer HiScroll dry scroll vacuum pumps can be easily connected to other Pfeiffer Vacuum products (such as turbopumps or display and control units) as well as to a higher-level external controller, via RS-485 or ProfiNet. The interface enables RPM regulation, situation-specific control of the fan and monitoring of the pump performance. This helps to minimize wear and noise emissions, and ensures longer maintenance intervals.

The integrated two-stage gas ballast and safety valve ensure process-specific and safe operation. The proven quality of Pfeiffer Vacuum components guarantees pump longevity. Easy maintenance enables short service times and the efficient motor helps to reduce electricity costs.

***Note: The final pressure is usually achieved after a certain running time. The run-in process can be accelerated by using a gas ballast and/or nitrogen. Tested base pressure during the quality control prior to delivery, according to ISO 21360. Quality control has been performed with a measurement instrument that is independent of the type of gas.