How did we Create the Revolutionary New Dry and Cure Process?

The Original Resinator’s Behind the Process: Crop-to-Cure®

PART 4 | Save the Terpenes!

Solution:

From the newly improved aromatic terpene profile achieved with the digital bleed valve from DigiVac’s StrataVac, The Original Resinator was now able to optimize freeze drying for their botanical products to retain the quality that customers expect, while bringing products to market faster. The research and experiments that went into the parameters for the bleed valve control benefits not only the user, but improves the overall quality of the cannabis.

The automated digital setting of the bleed valve can be placed in the chamber for a properly controlled environment with no added steps or moving parts needed. Controlled pressure bleeding improves the quality of the flower by preserving terpenes while also avoiding additional time and unnecessary oxidation in the freeze dryer. In addition, eliminating the liquid phase for the delicate process of preservation that occurs in sublimation.

The balancing act of low range temperature but high range pressure is what makes our partnership so unique to other research and machinery.

Benefits:

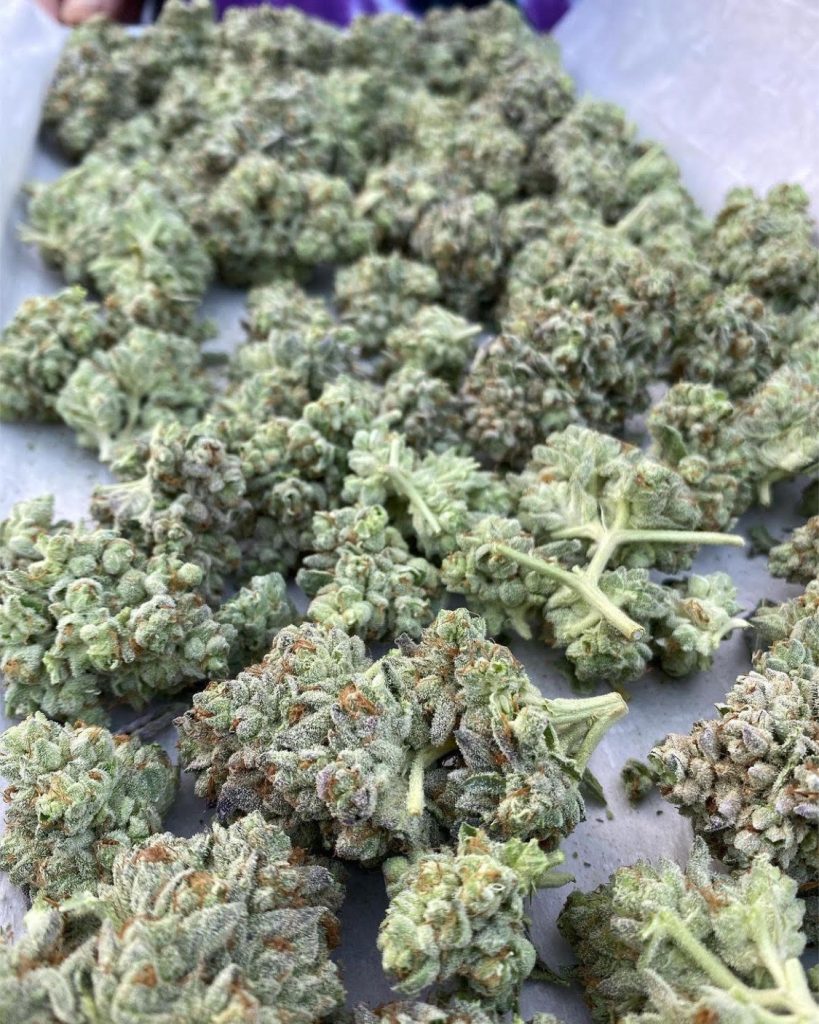

Adding an automated bleed valve to their freeze dryer bundles packages would increase the quality of the lyophilized botanical product and simplify vacuum control for their product offerings. Besides the time and preservation measures of the additional vacuum bleed valve, the other benefits of the Crop-to-Cure® technology are retaining the same size and shape of cannabis as when it was freshly harvested. This improves color, flavor, cannabinoid levels and desirable terpene profiles, as well as preservation and sterilization of products within all production stages (just to name a few).

These added bonuses are not only the ways The Original Resinator optimized the freeze drying of cannabis. Sanitation was one of the first added benefits mentioned before in previous articles. As well as the user experience, boasting a clean and extremely smooth smoke that is gentle on the throat and lungs.

“Because of the streamlined steps it decreases with the chamber“

But the unexpected added value in freeze drying was the potency results that were increased compared to traditional methods. The fact that The Original Resinator’s process maintains potency with no degradation of terpenes not only means better fragrance and taste; the results garner an average increase of as much as 3 -4% percent in total cannabinoids.

With DigiVac’s help we were able to start a true “save the terpenes” campaign. Now we are the tip of the spear as pioneers of a revolutionary new dry and cure process for your cannabis and hemp smokable flowers.

Conclusion:

Not only did The Original Resinator with the help of DigiVac find a way to increase productivity, production, and the quality of cannabis, it did so with the best means necessary. The Scientific Harvest Right freeze dryer model that went into the vacuum’s bleed valve not only revolutionized The Original Resinator’s models and products, but for customers already familiar with Harvest Right freeze dryers who now had a way to improve the functionally of it and optimize their own process. And at a price point that is accessible to hobbyist, boutique and commercial cultivators alike.

Overall the benefits are overwhelming and in summary The Original Resinator aided with DigiVac’s Vacuum control was able to create and optimize a process of their own intended to make cannabis processing significantly more time efficient while producing an entirely new SKU – “live dried”. Viva la live dried revolution!

Learn more about this inside look at TOR’s Behind the Process: Crop-to-Cure® in this 4 part blog series! What more info on Crop-to-Cure®? Check out their Q&A here!