Vacuum Gauge Calibration Services

DigiVac provides professional vacuum controller and vacuum gauge calibration services for the research and processing industries, which are led by DigiVac’s vacuum calibration experts.

We offer standard and NIST-certified results, including pre-calibration and post-calibration documented readings.

DigiVac recommends yearly calibration of your vacuum gauge or controller for ideal accuracy. Please review our options below, or fill out the form on this page, as it is the fastest way to initiate the process

We Calibrate to NIST Standards

The National Institute of Standards and Technology (NIST), is a measurement standards laboratory whose mission is to maintain the integrity and consistency of measurement standards in the US. NIST standards ensure consistency of measurement and are applied to digital vacuum instrumentation. Technical requirements are published in Handbook 44 that provides the "Specifications, tolerances, and other technical requirements for weighing and measuring devices".

Why is this important to you?

As a vacuum consumer, why is this important to you? You want to make sure that your vacuum gauge is consistent and reliable, providing you with the accurate information you require about the functioning of your system.

Thermal sensors have unique properties that can create slight changes in the measurement readings. At DigiVac we calibrate each sensor to the gauge so that they are a mated pair and will be consistent with our published accuracy specifications.

NIST Calibration Done Right

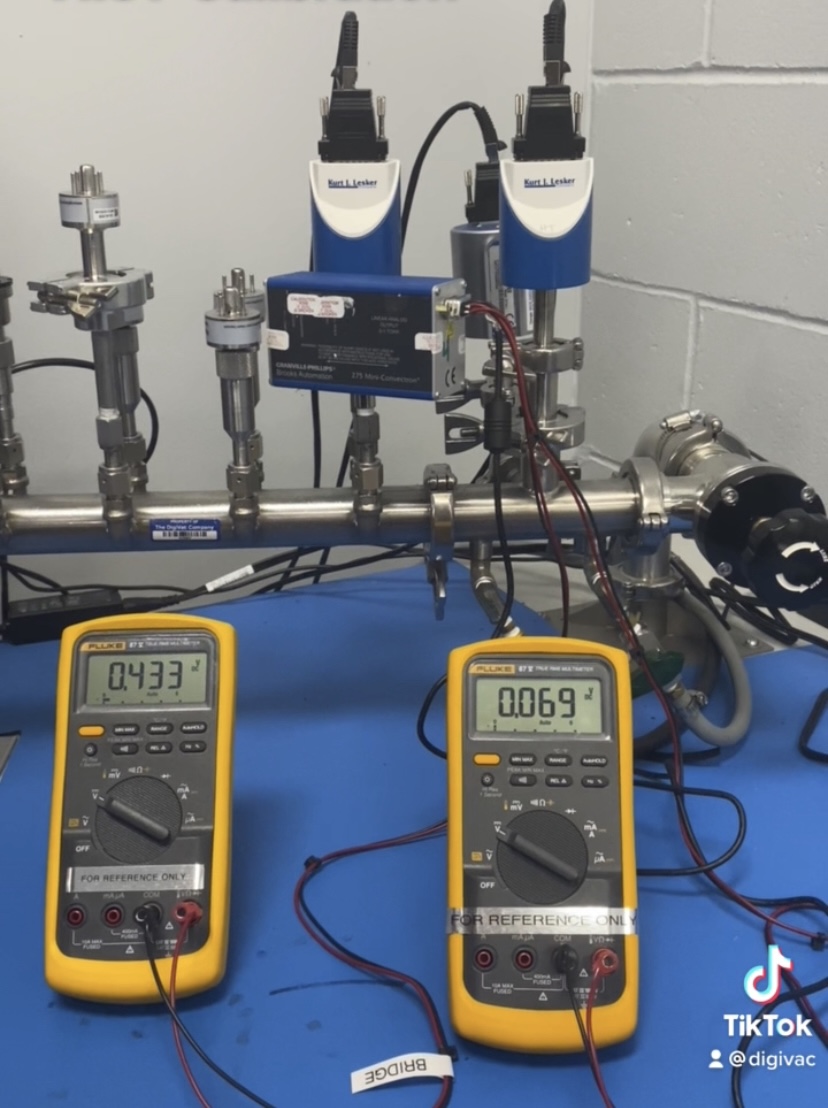

At Digivac, NIST calibration involves using a higher accuracy vacuum gauge calibrated by an A2LA certified lab to the vacuum gauge being tested. All vacuum instruments that leave the DigiVac factory are calibrated under real vacuum against a NIST standard.

Watch our team in action in the video below, as Digivac Head of Research and Development, Tom Bassi demonstrates the process of using the StrataVac Model 201 and 801W.

Calibration without Documentation

The main difference between this type of calibration and a NIST calibration is that the before (as found) and after data is not documented. Additionally, a NIST certification is not included with the gauge when it is sent back to the customer.

Need to get your Vacuum Gauge or Controller Calibrated, but you don’t need documentation? Then choose this standard vacuum gauge calibration service. Note: No documentation is provided. If you need NIST certification then choose NIST calibration.

How often do I need to calibrate?

We recommend that your vacuum gauge or vacuum controller be calibrated on an annual basis, but it may need to be done more often. Life sciences and cGMP laboratories are required to maintain tight specifications, which could necessitate calibration on a much more frequent basis.

The decision to calibrate a gauge should be made by the user based on usage, possible contamination and procedural obligations. When foreign matter comes in contact with the sensor, it alters the sensor characteristics. Those altered characteristics will yield a different pressure measurement over time.

Calibration frequency is also largely dependent on the type of service your vacuum gauge is used for.

- In clean, dry environments that are mostly nitrogen, calibration intervals may be extended.

- In vacuum drying or freeze-drying applications where the gauge is constantly bombarded in water, you may consider calibrating more often.

- In very dirty environments like heat treating, metalizing and oil purification, there is a likelihood of more frequent calibrations.

Before we can issue an agreement for return of any equipment, the DigiVac Decontamination Form must be filled out and signed by an informed and responsible member of your organization.

Featured Calibration Resources

Watch Our Calibration

In this video, DigiVac’s Head of Research & Development, Tom Bassi, demonstrates DigiVac’s calibration process for vacuum gauges. This is an inside-look at our calibration procedure!

Check out our Lead Technician, Hillary providing the know all of our calibration services for the GP 274 Mini Convection Gauge as well as its lead time! Did you know on average you will receive your newly re-calibrated gauge no more than two weeks after its sent in !?!!

Read Our White Paper

Read our white paper here. You will learn about many aspects of a calibration, including our different calibration options, what to expect, and DigiVac’s calibration procedures.