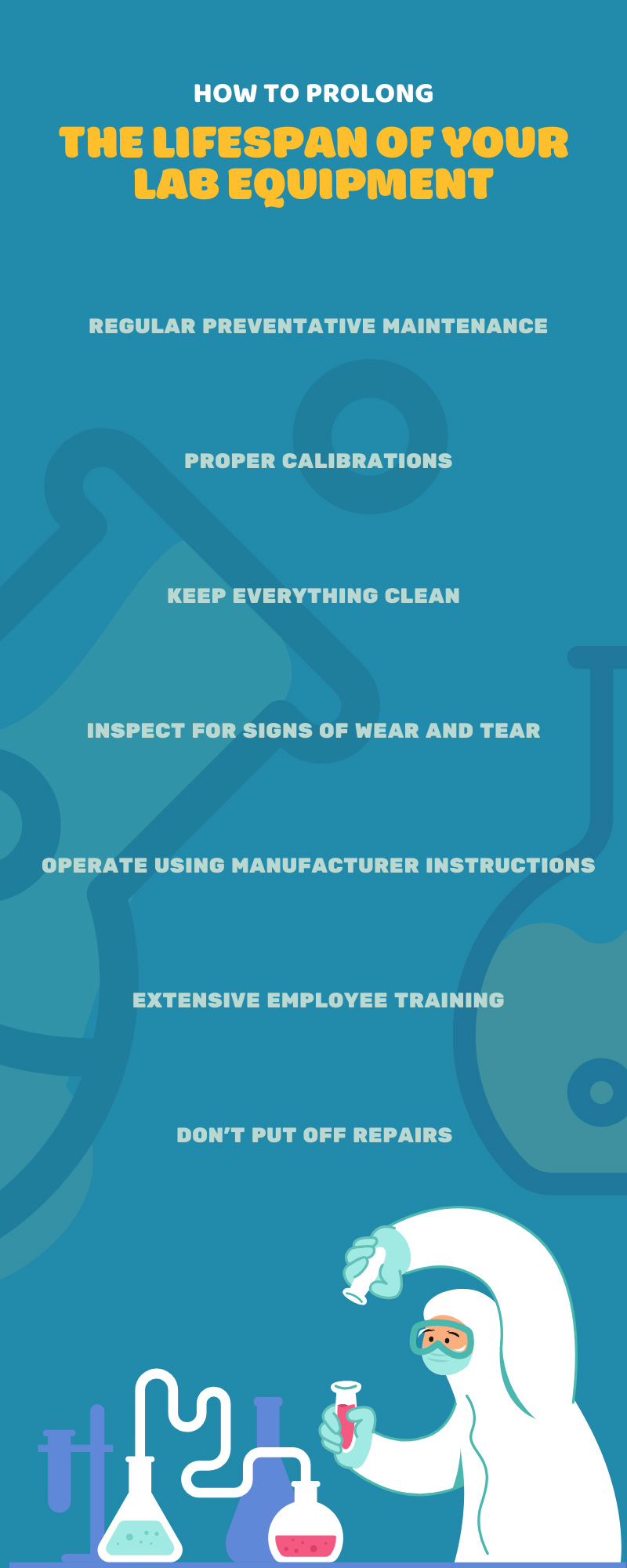

How To Prolong the Lifespan of Your Lab Equipment

Working in a lab setting requires a high level of extra care and scrutiny when setting up, operating, and taking care of high value laboratory equipment. If you’ve worked in a lab for an extended period of time, you know how important it is to take care of the equipment you work with every day. Depending on the lab, these instruments and equipment could be extremely sensitive, so it’s important to be gentle with them and understand how they work as well what to look for when it is time to get them serviced.

With most lab equipment, even the smallest inaccuracy can impact the accuracy of your results possibly leading to misinformation or a failed experiment. That is why you need to keep all your lab equipment good working condition. Because this equipment is so essential to successfully running a lab, you need to know how to make sure it lasts for a long time. In this article, we will provide tips on how to prolong the lifespan of your lab equipment.

Regular Preventative Maintenance

When working with delicate or sensitive equipment, it is important to know how to properly operate them and what types of outputs you should expect from them before you use them. A good place to learn how to operate any new equipment is to review the user manual or ask a more senior lab technician. The same thing applies to lab equipment maintenance. You can save yourself a lot of time and energy by staying up to date on its preventative maintenance, rather than always doing reactive maintenance. Waiting until your equipment breaks down or fails is only going to make the problem more difficult to deal with. A little time spent performing preventative maintenance can save you a lot of future headaches and keep your equipment lasting much longer. Consider setting up a scheduled maintenance schedule for your critical lab equipment like keeping tip seals on hand when it is time for doing maintenance on scroll pumps or keeping high quality vacuum rated oil on hand for rotary vane vacuum pump maintenance.

Proper Calibrations

Many of your lab equipment like vacuum gauges, controllers, and temperature data loggers require regular calibrations to help keep them working optimally and delivering the precise readings like they did when you first installed them. Most of these scientific instruments are good with an annual calibration, but some may require more frequent calibrations depending on your lab and the accuracy specifications required for your application. As mentioned, these are sensitive instruments, the accuracy of the sensors and probes can get out of spec over time with frequent use or contamination. A wide variety of instruments used in a lab setting need proper, professional calibrations in order to prevent them from getting skewed results. That’s why we offer vacuum gauge calibration to our customers—because we know how important accuracy is, and we want you to get the results you need.

Keep Everything Clean

It may seem quite simple and obvious, but one of the best ways to prolong the lifespan of your lab equipment is to make sure you clean it regularly and properly. While the cleaning process changes based on your specific instruments and how dirty your process may be, you cannot afford to skip this important maintenance practice to help keep your equipment working in peak condition. This should be the first step you take if you see that your lab equipment is not working as it should. Environmental or processing contaminates can make your scientific instruments less effective and eventually causing mechanical issues or inaccurate readings.

Inspect for Signs of Wear and Tear

While conducting your regular cleaning, check your equipment for signs of wear and tear. Over time, even the sturdiest constructed piece of equipment will wear down. The sooner you can spot where wear and tear, the better prepared you can be to replace or repair these problem areas before the shut-down or fail to work properly. A lot of scientific equipment has internal mechanisms that do need to be replaced when they start to break down so it is best to keep these on hand for when you need them.

Operate Using Manufacturer Instructions

Every piece of equipment comes with instructions on the best way to operate it. If you really want to prolong the life of your lab equipment, then review the proper way to install and operate your equipment consistent with the product’s user manual provided by the manufacturer. Following the manufacturer’s recommendations when it comes to how long to use the equipment, the proper method of cleaning it, and what kind of parts to use if you need to replace something will help prevent your equipment from aging prematurely. There could be specific ways that parts should be installed or cleaned so that you don’t get erratic readings or break sensitive internal electronics. No matter how skilled you may be, trust the words of the ones who built the equipment themselves to know what’s best for it.

Extensive Employee Training

No lab has the same people working in it forever. Newcomers will be coming in and out of the lab all the time. It is crucial that anyone who might need to interact with a certain piece of equipment be fully trained on its operation. Not only does this help to prevent new technicians from inadvertently damaging or straining the equipment, it also prepares them to be on the lookout for any issues that may arise with the equipment. Consider regular training classes not only for new technicians but also for regular staff to help serve as a refresher for safe operating procedures. Many companies offer videos on their websites on how to use their equipment that you could use a resource.

Don’t Put Off Repairs

Sometimes, if a problem seems like it shouldn’t be a big deal, you may feel tempted to procrastinate repairing it. Whether this delay is for monetary reasons or time constraints, it is rarely ever the right call to make. In most cases, ignoring problems with a piece of equipment will cost you a lot more in the long run. If you find signs of serious wear and tear or if you had a malfunction while you used it, do not ignore these problems, and simply hope they will go away. They won’t. They’ll only get worse, and the only remedy for such problems is to deal with them immediately.

Why Should You Care About Prolonging Lab Equipment Lifespans?

Beyond the obvious benefits of saving money on repairs and new equipment and avoiding inaccurate results, why do you need to care so much about prolonging the lifespan of your lab equipment? Two reasons….avoiding downtime during repairs and making research decisions on inaccurate results. Critical lab equipment requires love and care to make sure they keep delivering peak performance for years to come. And it makes your life less stressful without having to worry whether you can trust the readings the equipment is giving you or have to deal with a sudden failure. The longer you can keep your equipment running at peak performance, the less hassle your future self will have to deal with.

DigiVac is well aware of how important it is to have the right equipment for a successful lab. That is why we supply our customers with the best equipment possible, and it’s why we work so hard to make sure you get the right equipment for the job. Whether you are in the market for something new or need our calibration services, DigiVac is here to help.