If you’re new to vacuum technology, it may not be immediately clear why vacuum ovens are so useful. What does the introduction of vacuum provide to the operation, and why is it important to have? It might surprise you to find out how common the use of vacuum drying ovens is in many different industrial, manufacturing, and processing sectors. Whether you are in the market for a vacuum oven yourself, or simply curious about the technology, we’re happy to provide the information you are looking for. In this article, we will go over what this technology is, why we need to use it, and the different industries that use industrial vacuum drying ovens in their day-to-day operations.

What Is a Vacuum Drying Oven?

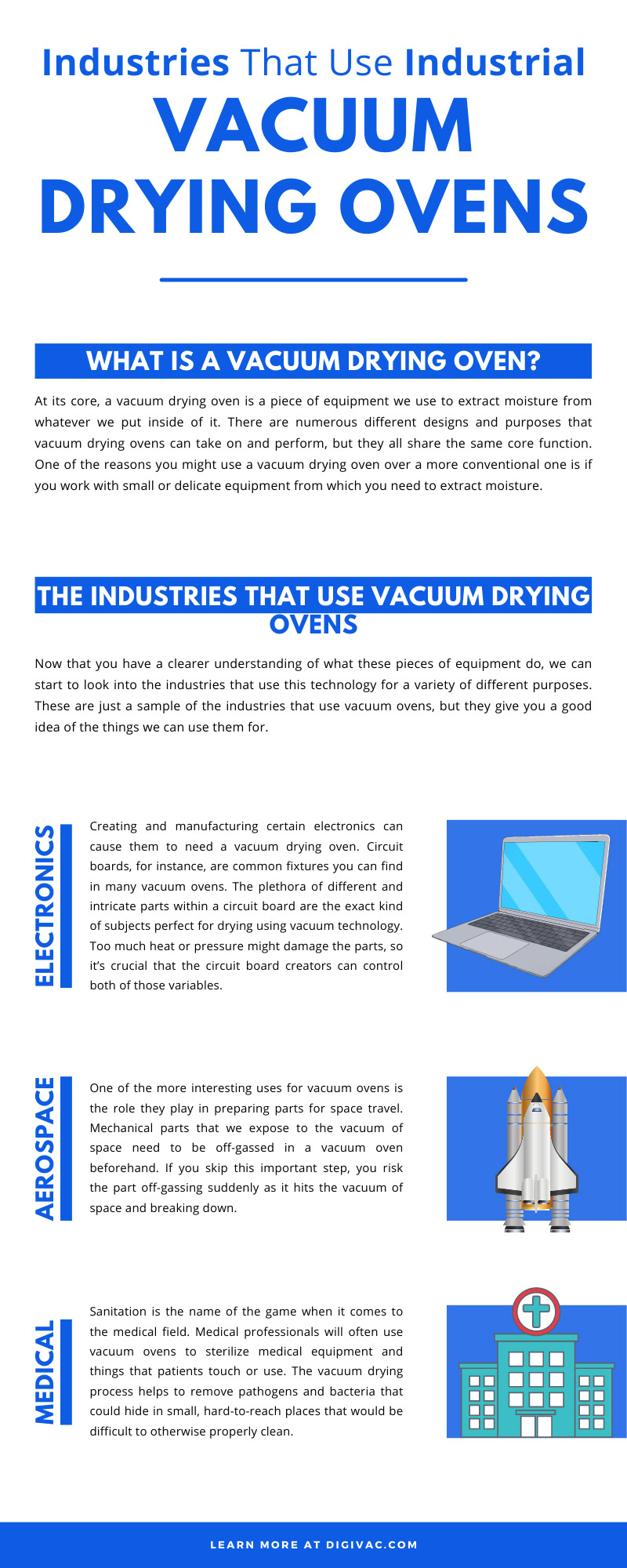

At its core, a vacuum drying oven is a piece of equipment we use to extract moisture from whatever we put inside of it. There are numerous different designs and purposes that vacuum drying ovens can take on and perform, but they all share the same core function. Vacuum ovens can function at high temperatures from around 200 to 250 degrees Celsius. The modern vacuum ovens of today feature high quality and rugged pressure chambers, electronic controls for temperature, either analog or digital vacuum gauges, stainless steel components for clean manufacturing, and industrial gasket seals.

Vacuum drying ovens have applications in the field of engineering, laboratory research, processing, pharmaceuticals, and electronics manufacturing. They are normally used for sensitive drying procedures like removing flammable elements or drying very small parts.

The Major Purposes of Vacuum Drying Ovens

Though we have already mentioned the core function of vacuum drying ovens, it’s important to go through all of the different purposes that vacuum ovens have. These are not the only reasons to use a vacuum oven, but they tend to be the most common.

Moisture Removal

As we stated above, the removal of moisture from equipment or delicate medicinal products is one of the key functions of a vacuum drying oven. These ovens are ideal when the equipment or products that require moisture to be removed are either fragile or sensitive to changes in temperature. Usually, near the end stages of production for things such as microchips and medical devices, manufacturers use vacuum ovens to remove any excess moisture. Some manufactured products are porous. Moisture can hide out in these pores eventually causing the product to fail, vacuum drying ovens serve to remove this hidden moisture gently and completely.

Off-Gassing

Off-gassing is the process of removing all chemicals from the exterior of metallic components. It is also called out-gassing. Using a vacuum oven, we can take away sources of moisture—such as what is left behind by certain sealants and lubricants—that might interfere with the function of the component once it is in use.

Chemical Reaction Prevention

When you use a vacuum drying oven, you have much more fine control over what happens inside the chamber. When you control important variables such as temperature and pressure, you can prevent certain chemical reactions from happening. For example, we can use vacuum ovens to prevent oxidation from occurring on the surface of a specific metallic part or oxidation of certain medicinal products. Vacuum pressure controllers can be added to vacuum ovens to help optimize the vacuum drying process and provide a gentler drying process. Modern vacuum controllers provide recipe control as well as precise proportional control and venting (bleed vacuum control).

Another benefit of vacuum ovens is the gentle and controlled drying functionality so the oven does not disturb powdery and light items.

Bake-Out

A bake-out refers to a method in which we speed up the process of off-gassing. Again, by being able to control temperature and pressure to a fine degree, we can increase the temperature inside of the chamber to force certain volatile chemicals out of whatever product is inside. Combined with the ability to reduce chemical reactions, this makes baking out those volatile chemicals much safer and more efficient.

The Industries That Use Vacuum Drying Ovens

Now that you have a clearer understanding of what these pieces of equipment do, we can start to investigate the industries that use this technology for a variety of different purposes. We are going to take a deeper dive into some of the industries that use vacuum ovens, but you may be surprised

They are often used as the final step in the production process for implantable medical devices, semiconductors, epoxies, essential oils, and many packaged food products.

These are just a sample of the industries that use vacuum ovens, but they give you a good idea of the things we can use them for.

Electronics

Electronic manufacturers and the semiconductor industry use vacuum ovens to dry very delicate electronics and cure the coatings of printed circuit boards.

The plethora of intricate parts within a circuit board are ideal products for the use of vacuum technology when drying since you are able to dry parts at a lower temperature utilizing vacuum. Too much heat or pressure might damage the parts, so it is crucial that circuit board manufacturers can control these variables.

Aerospace

One of the more interesting uses for vacuum ovens is the role they play in preparing parts for space travel. Mechanical parts that we expose to the vacuum of space need to be off-gassed in a vacuum oven beforehand. If you skip this important step, you risk the part off-gassing suddenly as it hits the vacuum of space and breaking down. Another use for vacuum ovens in the aerospace industry is, for thermal processing of equipment in the vacuum chamber which helps ensure that the equipment remains highly accurate and reliable and proven to be able to withstand extreme temperature conditions.

Medical

Sanitation is the name of the game when it comes to the medical field. Medical professionals will often use vacuum ovens to sterilize medical equipment and things that patients touch or use. Sanitization isn’t the only use for vacuum ovens in the medical and pharmaceutical fields, these industries also use vacuum ovens to remove humidity and moisture when manufacturing and processing drug products like the fine power drug components used in the medications you may use on a daily basis.

The Benefits of a Quality Vacuum Drying Oven

Quality matters when it comes to vacuum ovens; there is no doubt about that. Here are some of the reasons you want to get a high-quality vacuum oven you can rely on.

- Precise and Uniform Drying. The purpose of a vacuum drying oven is to uniformly remove moisture from the surface of parts. You want to have exacting control of both the temperature and the vacuum pressure within process from start to finish.

- Long-term Use. Properly constructed vacuum ovens will last you an exceptionally long time as long as they are properly maintained.

- Accurate Gauge Readings. Accurate temperature and pressure gauges are essential to your success. Adding a vacuum pressure controller to your vacuum oven can help you optimize and have more control over you vacuum drying process.

If you are looking for a vacuum drying oven for sale, we have your back. Here at DigiVac, we strive to provide our customers with as much information as possible so you can make an informed decision about your purchase. We offer high-quality vacuum ovens and have conducted research on which vacuum pumps and vacuum controllers are best suited for different capacity vacuum ovens. We will be more than happy to work with you on providing solutions to your unique problems and vacuum application needs.