Description

FYRA distillation vacuum controller – DigiVac’s Latest Innovation

Vacuum Science Simplified

We know vacuum applications can get complicated, and the FYRA was created to deliver scientific measurement and vacuum control simply. The FYRA can be easily integrated into almost any system in the market with its ability to drive multiple types of sensors (piezo, thermal, active, passive, and capacitance manometers) and its high configurability.

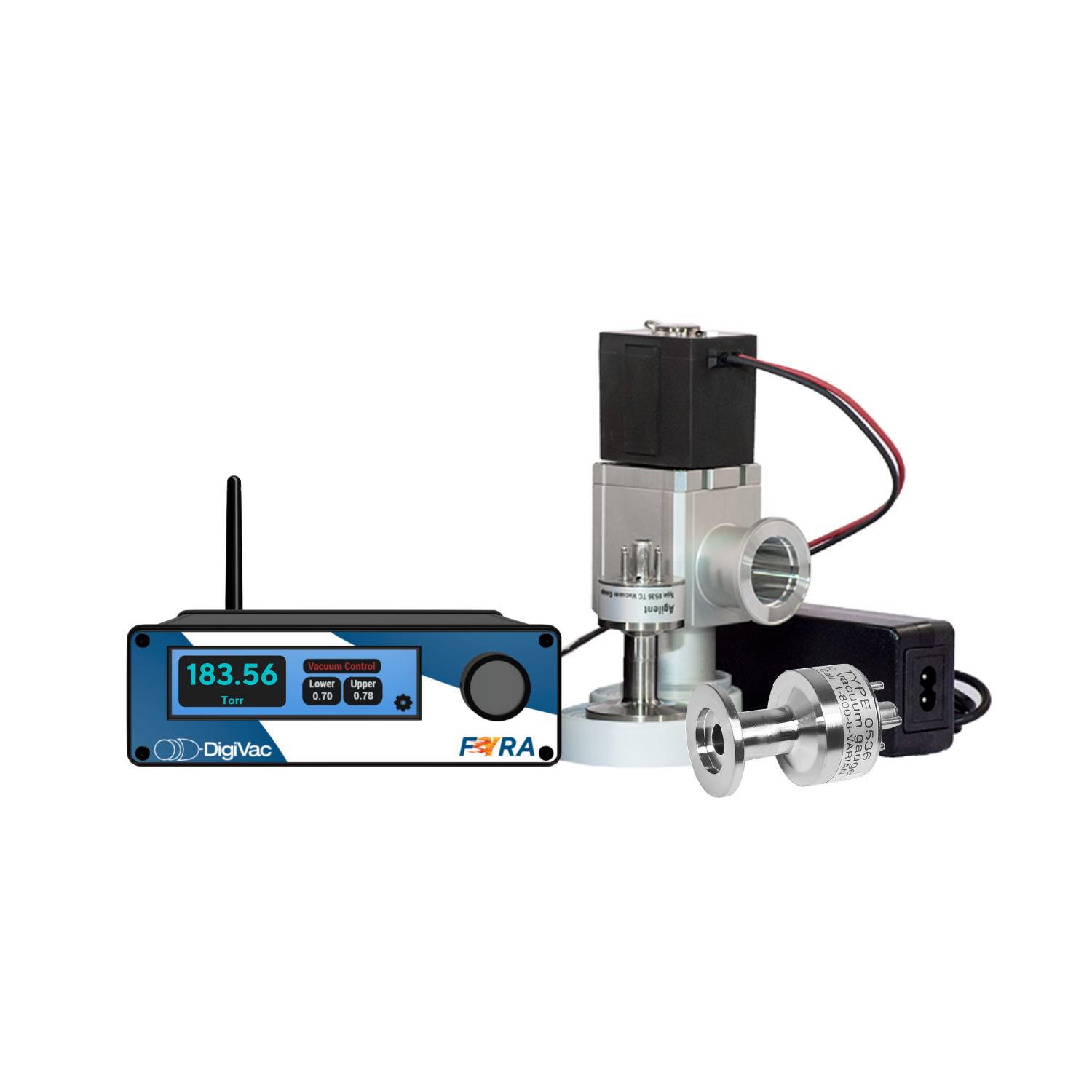

The DigiVac FYRA Vacuum Controller Distillation Bundle specifically was created to include diagnostic capabilities. It has 2 sensors – one connected to the system and one connected to the roughing pump. By comparing the readings between the two sensors, you can detect whether everything is running as it should or if there are any potential leaks or problems.

Package Includes:

- FYRA Vacuum Controller

- (2) Agilent 536 KF25 Thermocouple Sensors and driver cards

- (1) Bellows-type Throttle Valve and driver card

- Options: WiFi

- Optional: Installation Kit (Aluminum Wing Clamps + Stainless Steel/Viton Centering Rings). Please fill out the product inquiry below to add this option.

Bellows KF25 Valve: works by throttling the pressure between the vacuum pump and the process to control the vacuum level or to isolate the vacuum pump | Enables vacuum pressure control a solenoid valve for throttling pump suction.

- Control Range: 10 millitorr to 6 Torr

- Measurement Range: 1 millitorr to 760 Torr

- Range with accuracy: 10 millitorr to 6 Torr

- Benefits of Bellows Throttle Control: With the KF25 1″ orifice you get better and faster throughput | ideal for processing high volumes | Extends life of pump by enabling pump to run closer to it’s base pressure

Optional WiFi Connection

View pressure in real time through vacuumnetwork.org, and log data through the USB interface.

Choose Digivac for your Distillation needs.

Example of a FYRA Application

- Distillation Vacuum Controller Applications— R&D: Vacuum Ovens, Vacuum Furnaces, Vacuum Bagging or Composites

- Botanical Processing: Rotary Evaporation, Short Path Distillation (1 Head Kit), Extractions

- Use Case Example— To maintain specific pressure levels in a vacuum oven at about 2 Torr to avoid removing target terpenes and only removing water

Alternative Solutions

This set-up can be used to monitor both sides of a 2 Head Distillation set-up and a Bullseye Precision Gauge can be used to monitor the pressure at the roughing pump. This version comes with a Bellow-type throttle valve which works by throttling the pressure between the vacuum pump and the process to control the vacuum level, or to isolate the vacuum pump. It enables vacuum pressure control using a solenoid valve for throttling pump suction. Throttle Vacuum Control from 10 mT to 6 Torr with a high flow bellows valve helps you monitor and control molecular flow in your distillation application.

Short Path Distillation Summary

Short path distillation is a process that occurs after extraction. It is a type of botanical processing, generally utilized for the molecular separation of botanical fluids to achieve high potency. “Short path” refers to the short distance the oil travels, relative to the notoriously large industrial distillation units most people know. Wiped film distillation is a type of short path distillation.

Read our Distillation Application Note

Vacuum for Short Path Distillation

One of the primary purposes of using vacuum in distillations is to lower the temperature required to achieve a boiling point. The target product in a distillation could either be the remaining product, the distilled product, or a purified product. The vacuum associated with a distillation depends on the product to be distilled. Volatile substances are likely to undergo vacuum distillations above 1 Torr. Composite distillations typically require precise pressure control in the region above 1 Torr.