DigiVac Case Study: Automatic Vacuum Pump Down Control System

Featuring the DigiVac StrataVac Touch vacuum controller and Agilent IDP-10 vacuum pump

“A large research laboratory reached out to DigiVac to help them automate their Vacuum Stations. They wanted to move from their current process that included manually-actuated electronic valves to an automated vacuum control system.”

READ THE FULL CASE STUDY:

You can access and continue reading the full case study by clicking here.

WATCH OUR VIDEOS:

You can watch several videos describing the new configuration by clicking any of the hyperlinks below.

- Overview of Our Pump Down Solution

- StrataVac Touch Interface for Automated High Vacuum Pump Down

- StrataVac Touch Automatic Pump Down Personality

- Purpose of Each Valve in Our Solution

- Instrumenting our Pump Down Solution to Verify Function & Safety

- Bullseye’s Use in Understanding Vacuum System Function & Performance

BROWSE OUR IMAGES:

The images below show the progression of the case study. More information on each of these figures can be found in our full case study.

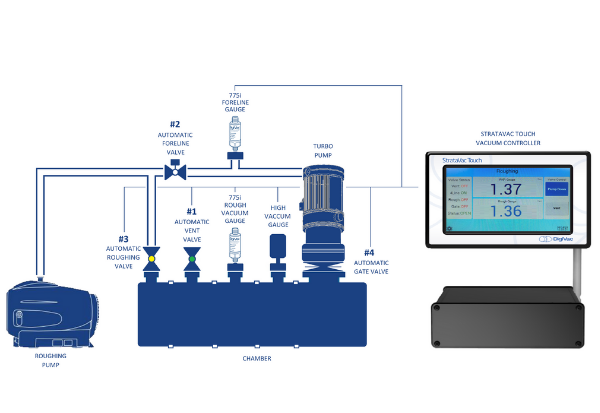

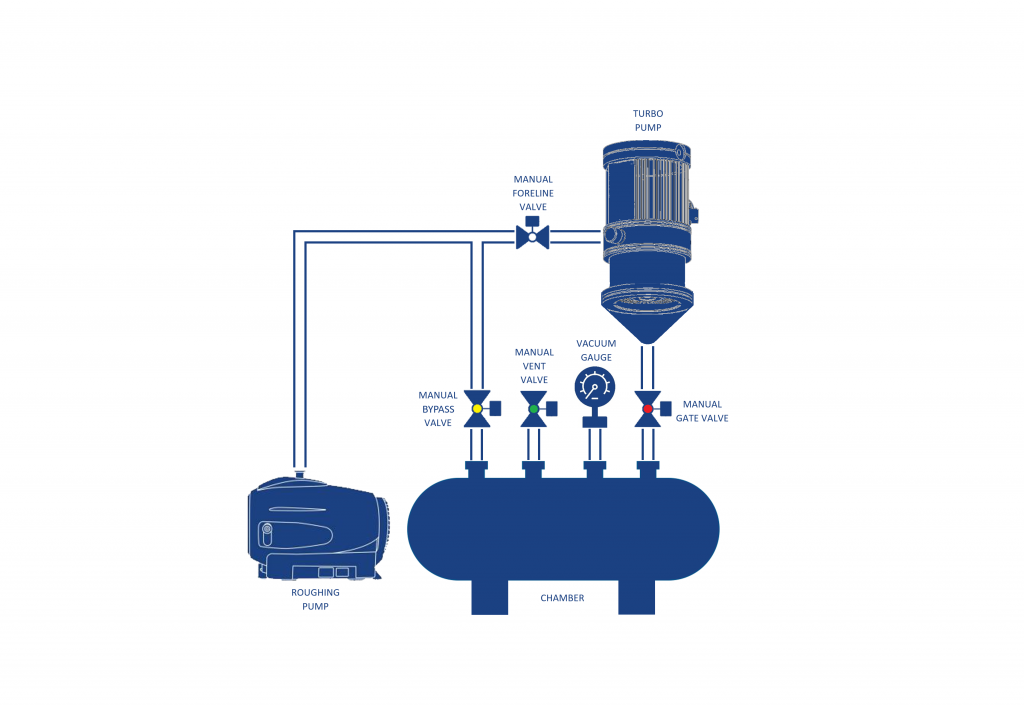

Figure 1. Customer’s Manual Configuration

The customer’s setup consisted of multiple vacuum systems, each having a number of electrically powered pneumatic valves which required a technician to manually operate.

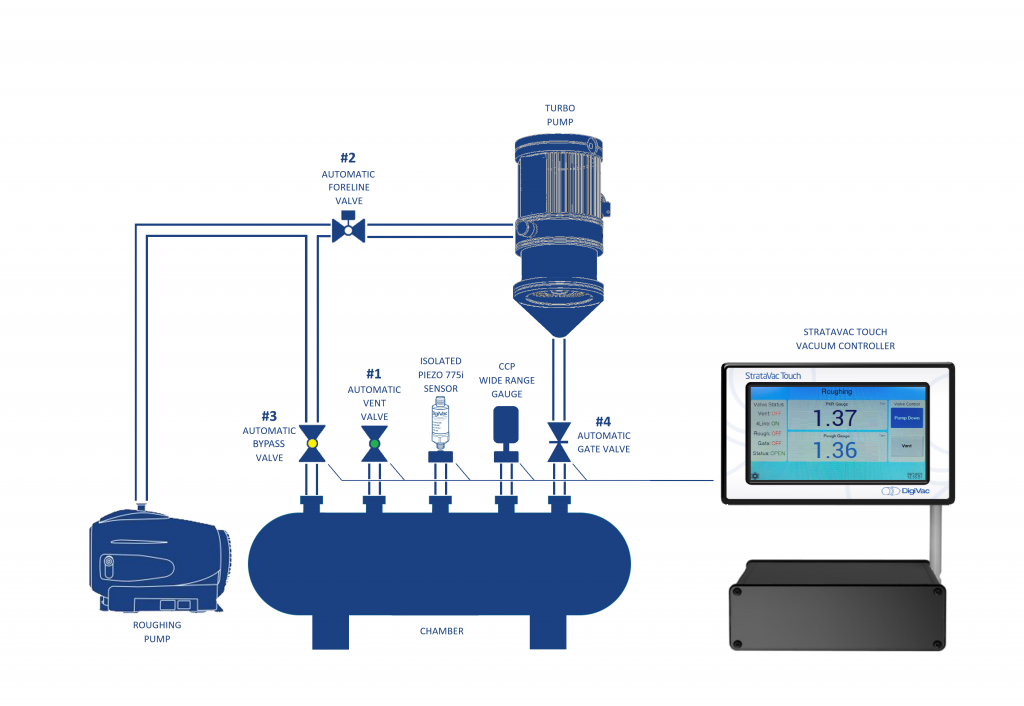

Figure 2. Customer’s Automatic Configuration

A sophisticated automated vacuum control system requiring minimal supervision or operation, using advanced software-controlled processes to pump and vent a chamber in accordance with the customer’s vacuum process needs

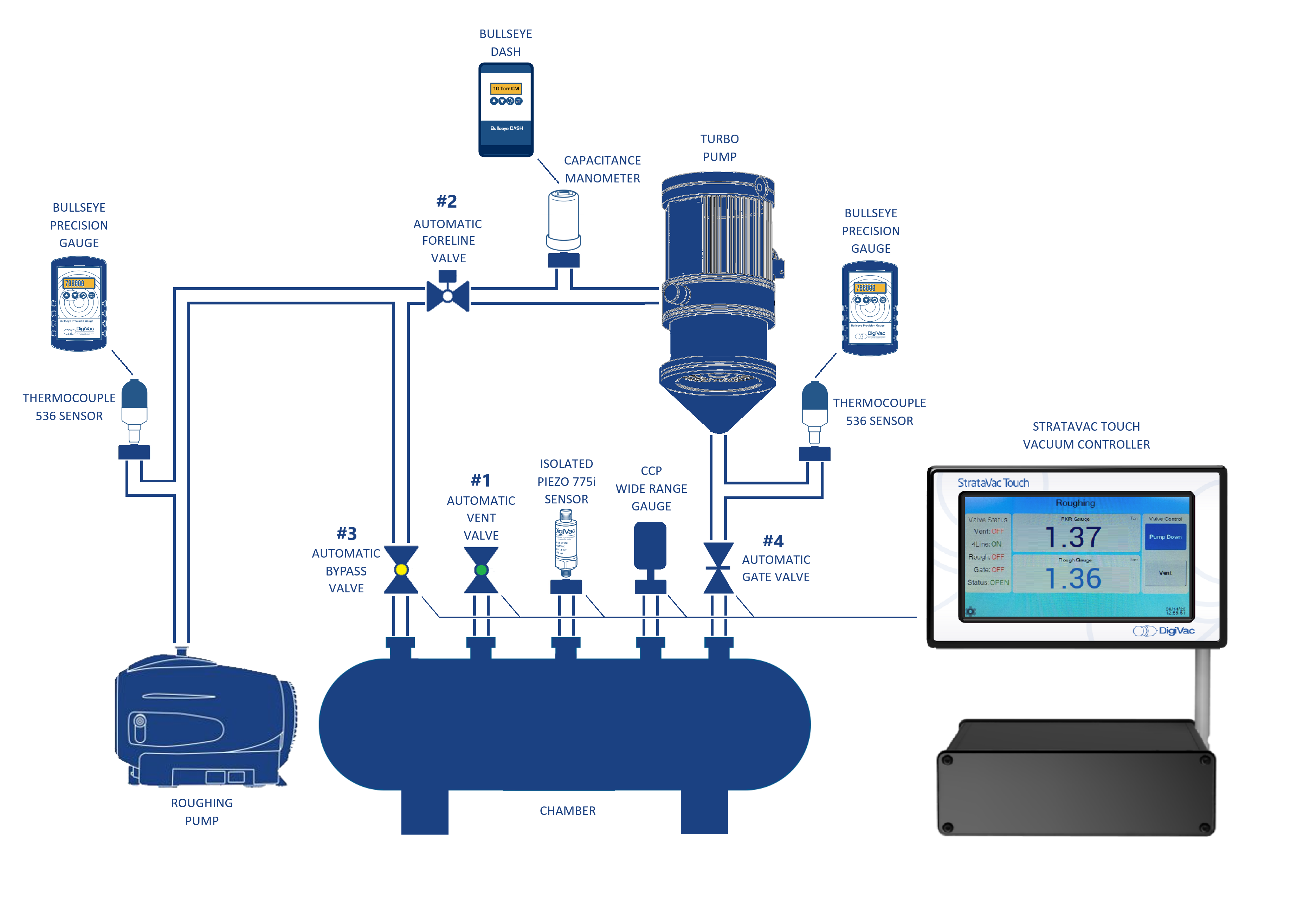

Figure 3. Customer’s Validation Configuration

Adding additional instrumentation for verification of automated system

Thank you for reading this blog. Are you looking to automate your vacuum system? Give DigiVac a call at (732) 765-0900. Or, contact us and let us help you develop the best solution to meet your needs.

To learn more about the DigiVac StrataVac Touch, click here.

To learn more about Agilent Vacuum Pumps and accessories, click here.