Description

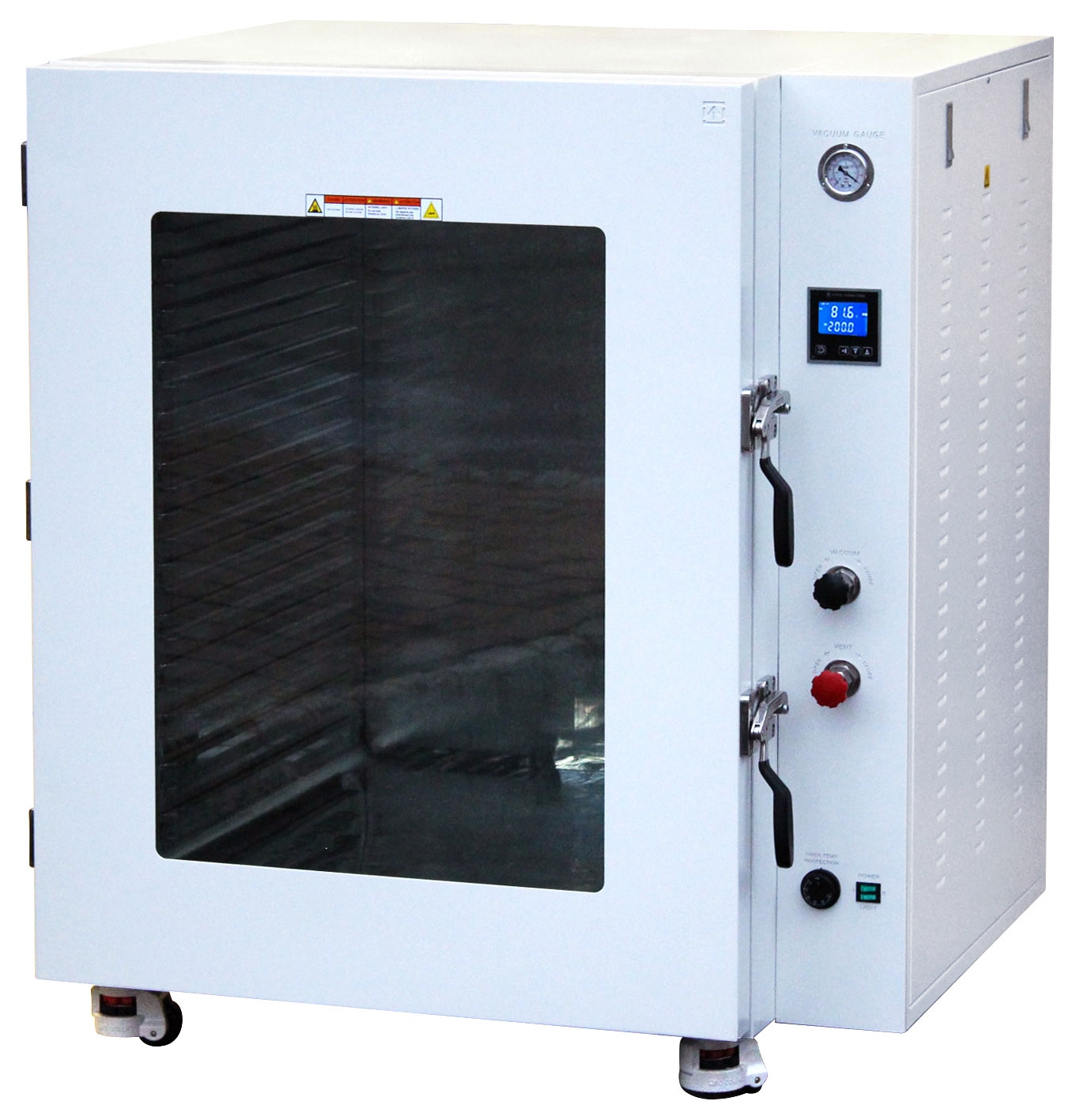

16 CF Vacuum Oven from Across International | ETL | Up to 250C

Introducing the new Across International ETL certified 16 CF vacuum drying oven (cubic feet), this certification is required by many municipalities, and it also provides a higher standard of equipment safety and lifespan. Also come standard is the secondary over-temp protection dial, 2.5X larger internal tubing for a quicker vacuum purge and release, and a secondary door handle to provide a better sealing on the door gasket. Comes in 220V and backed by a 2-year warranty.

- New KF25 inlet filter keeps your oven clean at all time (included with oven purchase)

- The most sanitary working environment, while last for decades without maintenance.

- The most accurate and stable vacuum gauge measurements.

- Built-in secondary over-temp dial for added protection.

- Complete control over vacuum and vent rates, while also largely enhanced durability.

- Built-in white LED lights

- Higher productivity and superior quality products with minimal processing time.

- Exceptional durability and ease of maintenance.

SST (stainless steel) tubing refers to internal tubing and compression. external tubing not included.

Every one of our vacuum ovens goes through a 2-time 24-hour vacuum leak test, and is quality controlled in New Jersey or Nevada before leaving our warehouses.

About this Vacuum Oven Series

Every one of these vacuum ovens goes through a 2-time 24-hour vacuum leak test, and is quality controlled in New Jersey or Nevada before leaving either warehouses.

IMPORTANT! NEVER LEAVE YOUR OVEN UNATTENDED WHILE OPERATING. DigiVac and Across International are not responsible for any loss of material inside of the oven.

Vacuum oven specifications

| Electrical requirements | 220V +/-10% 50/60Hz 1-PH 21A, 6,000 watts |

| Chamber | Size: 25.6 x 30 x 35.5″ Material: Stainless steel Capacity: 16 cubic feet |

| Heater | Layout: 5-sided heating Total wattage: 6,000W Distribution: left 860W x 2, right 860W x 2, top 400W, bottom 840W, back 330W x 4 |

| Temperature control | Controller: low proportional gain, microcomputer PID controlled with LCD display Range: ambient to 250°C (480°F) Display units: Fahrenheit or Celsius Uniformity: ± 7% of setpoint Dwelling timer range: 1 to 9999 minutes Heating speed

|

| Vacuum | Ultimate vacuum level: better than 500 microns/millitorrs (may vary based on your altitude, click here to learn more) Mechanical gauge range: 0 to 30 inch mercuryDigital Vacuum Gauge or Vacuum Controller Sold SeparatelyVacuum port: KF25 flange x 1 Vent port: KF25 flange x 1 Vacuum pump: Sold separately |

| Weight | Unit: 800 Lbs, shipping: 1200 Lbs |

| Dimensions (WxDxH) | Unit: 44 x 38 x 51.5″ Shipping: 50 x 45 x 60″ |

| Shelves | Shelf size: 25 x 30″ (WxDxH) Material: aluminum Style: pan-shape Capacity: 26 shelves max. Comes standard with oven purchase: 13 shelves Total area with 26 shelves: 89 sq ft or 12,857 sq inch Distance between the most adjacent shelves: 1.25 inches |

| Door gasket material | Silicone or Viton |

| Observation window | 1/2″ tempered safety glass |

| Safety | Built-in circuit breaker Overheat shutoff protection Secondary over-temp protection dial |

| In-door lights | White LED (pre-installed) |

| Compliance | ETL tested to UL and CSA standards, ETA 3/2021 |

| Warranty | 2 years |

Features:

- New KF25 inlet filter keeps your oven clean at all time (included with oven purchase).

- Six well thermo-conductive aluminum heated shelves with individual in-shelf temperature sensor, heater and digital temperature controller.

- All stainless steel internal vacuum tubing and compression fittings that holds vacuum 10 times longer and deeper than with rubber tubing. They also provide you the most sanitary working environment, while last for decades without maintenance.

- Oil-filled mechanical vacuum gauge ensures the most accurate and stable measurements.

- Built-in secondary over-temp dial for added protection.

- Adjustable vacuum and vent port with needle valves gives you control over vacuum and vent rates, while also largely enhanced durability.

- 4th gen low proportional gain temperature controller keeps your oven temperature accurate.

- Built-in white LED lights

- Best choice for the curing and converting of oil extracts. With deep vacuum level, they can operate at temperatures which allow the degassing/purging process to occur rapidly, thus increase productivity and allow for the production of superior quality products with minimal processing time.

- Dual layer observation window with 3/4″ tempered safety glass.

- Easy-to-clean stainless steel interior for exceptional durability and ease of maintenance.

- A vacuum environment lowers the boiling point (great for processing heat sensitive materials) and reduces drying time for materials like paste or powder which cannot otherwise be easily dried.

- Built-in alarm alerts you when oven has been shut down by safety circuitry due to out of range temperature.

- Built-in station-able swivel casters with locks for ultra-portability.

- All ovens shipped from our Nevada or New Jersey locations for quick delivery, and come with one year warranty and lifetime US-based parts and service support.

Manufactured in accordance with

- UL 61010-1

- CSA C22.2

- ISO 9001:2000

- ISO 12100-1:2003, ISO 12100-2:2003

- EN1050:1996, EN294:1992, EN60204-1:2006

- CE

| Standard package

|

DIGIVAC Recommends

Vacuum Pumps: IDP10 (6 CFM) or the IDP15 (9 CFM)

Vacuum Control: VPC with VPPM Software for running recipes or RAMP control, SNAP Vacuum Controller for Automated Vacuum Drying Process Control or the StrataVac Touch with innovative Dinamo Valve

Benefits of Vacuum Control on Vacuum Ovens:

- Providing precise control to the drying process enabling a more repeatable drying process and drying result

- Slowing down the initial pump down of a vacuum drying process helps do 2 things: ensures lighter materials are not sucked into the vacuum pump and ensures more delicate materials are not put under undo molecular stress

- Enabling the sequential separation of components to be removed while leaving others like in the example of residual solvent evaporation (Different solvents have different boiling points)

VPPM software combined with the Vapor Pressure Controller (VPC) allows you to set up a profile for your vacuum system, determining when it holds pressure or ramps up/down. Additionally, this software allows you to set a timeframe, in seconds, of how long each case occurs.

For multiple vacuum oven control with one vacuum controller consider the Concerto. The Concerto vacuum controller can control up to 4 vacuum ovens with one pump. We would recommend the IDP15 for controlling multiple vacuum ovens with the Concerto.