Description

SNAP Vacuum Controller | Simple, Nimble, Automatic Process Controller with up to 10 Recipes

New features: Faster Venting with external valve, More steps per recipe (now 24) for evacuation purge cycles, and PLC control with Analog output

SNAP: Automatic Vacuum Process Controller | Vacuum control and venting with the touch of a button or twist of a dial

- Vent your vacuum chamber or equalize your system with the touch of a button instead of pulling hoses or turning valves

- Treat material in chamber more gently by implementing kinder ramp rate controls which is ideal for freeze drying, vacuum drying or lyophilization applications

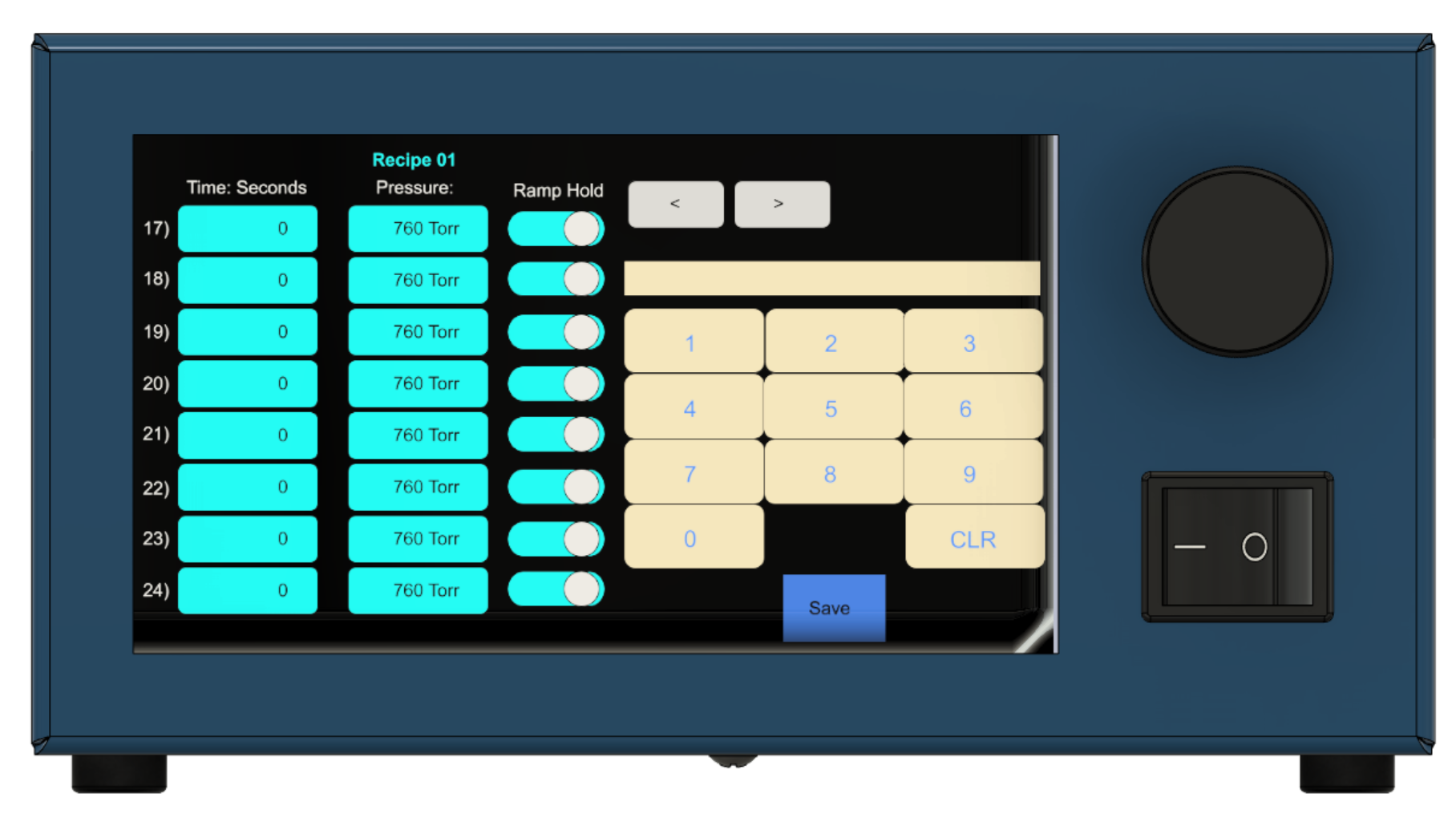

- Vacuum Controller with onboard ramp rate recipe control. Allows you to program up to 10 recipes with up to 24 steps in each recipe based on time and pressure setpoints.

- Dashboard pushbutton control for START, STOP functionality for each channel allows you to automatically vent or isolate your system with a push of a button

Ideal for automating and simplifying vacuum chamber pressure control.

- Vacuum Flange: KF25

- Measurement Range: 1 Torr to 775 Torr (standard)

- Control Range: 2 Torr to 760 Torr

- Integrated Sensor: Isolated Piezo sensor

- Need millitorr range?: SNAP has a RJ45 Port for adding an additional sensor to extend the measurement range. We recommend the addition of the DCP Quantum to be able to monitor and control from 0.01 Torr to 1000 Torr.

Precise Flow and Process Control

SIMPLE – SIMPLIFY YOUR LAB & CONTROL MORE WITH LESS

- Applications: vacuum chamber (from 1 liter to 1000 liters) research, vacuum ovens/vacuum drying, vacuum furnaces, large scale food processing, microwave drying, composites, rotary evaporators, falling film systems

- Fine control of target vacuum pressure for more precise processing and research

- Enables using reliable and long lasting rotary vane pumps & dry scroll pumps in applications where diaphragm

pumps were previously required - Keeps vacuum pumps near their base pressure resulting in greater longevity

NIMBLE – MAXIMIZES THROUGHPUT & PUMPDOWN SPEED

- Largest flow paths available to insure maximum flow for faster evaporation

- Maximize throughput and pump down speed with a 20 mm vacuum path (almost full KF25 orifice)

AUTOMATIC PROCESS – PRECISION CONTROL & INTUITIVE DESIGN

- Automatic Vacuum Process Controller | precise automated control with programmable recipes and graphing of vacuum levels

- Innovative valve control performs both proportional throttle and bleed vacuum control (vent to atmosphere)

- The integrated bleed design allows you to quickly vent to atmosphere to stop bumping during processing

- Numerical readings right on the LCD screen and one touch buttons: VENT, CLOSE (isolate, close all valves) and FULL VAC (fully opens the valve for vacuum pump and closes the vent valve)

- Analog out, 0-10 volts DC Analog in

- Onboard Recipe Control: The SNAP can have up to 24 individual steps in the recipe screen, time (minutes or seconds) in any step can be up to 999 minutes in duration. We can ramp or hold….Ramp is work our way up to the setpoint gradually, hold is just “get there” and stay.

SNAP Vacuum Controller Wetted Material:

- Viton

- 304SS

- 316SS

- PTFE 567

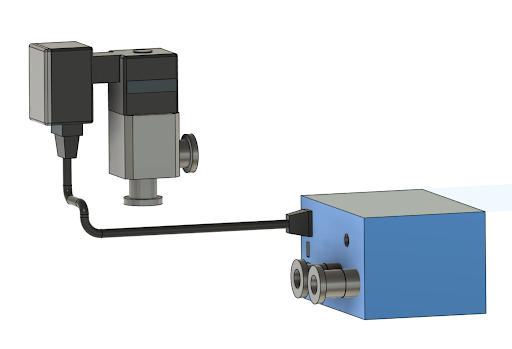

External Valve Option

The Time-Based Vacuum Differential Control is a sophisticated functionality integrated into the SNAP vacuum controller, designed to optimize vacuum control performance by dynamically regulating an external valve based on vacuum differentials (VD) within predefined time intervals (VDW). This feature enhances process efficiency by ensuring that the vacuum level reaches the setpoint within the specified time.

Operational Mechanics:

When configured, the Time-Based Vacuum Differential Control continuously monitors the vacuum level against the user-defined setpoint. If the desired vacuum level is not attained within the specified time, the controller triggers the external valve to open. The valve modulation is performed with precision to achieve the desired vacuum level efficiently.

Configuration:

Users can access the Time-Based Vacuum Differential Control settings through DVCUP. Configuration involves setting two primary parameters.

- Time Interval (VDW): Define the time interval within which the vacuum should reach the setpoint.

- Vacuum Differential Threshold (VD): Specify the allowable vacuum differential from the setpoint within the defined time.

VDW is defined in seconds, while VD is defined in Torr.

If the vacuum level is not within VD torr of the user inputted setpoint within the time interval of VDW, the external valve opens up.

Example:

VD: 10

VDW: 10

The controller triggers the external valve to open so the system can vent more quickly to the next setpoint.

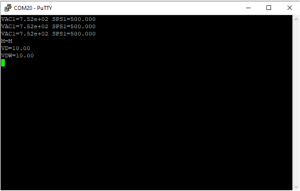

DVCUP Example:

Here is an example of the SNAP connected using DVCUP. The commands for the variables are as follows.

To query the current value:

VD?

VDW?

To assign a new value:

VD=(x) in Torr

VDW=(x) in seconds

DVCUP will not echo the command; it will only display the response.

Product Demonstration Videos

SNAP Controller Hardware

- How to Connect our SNAP Vacuum Controller

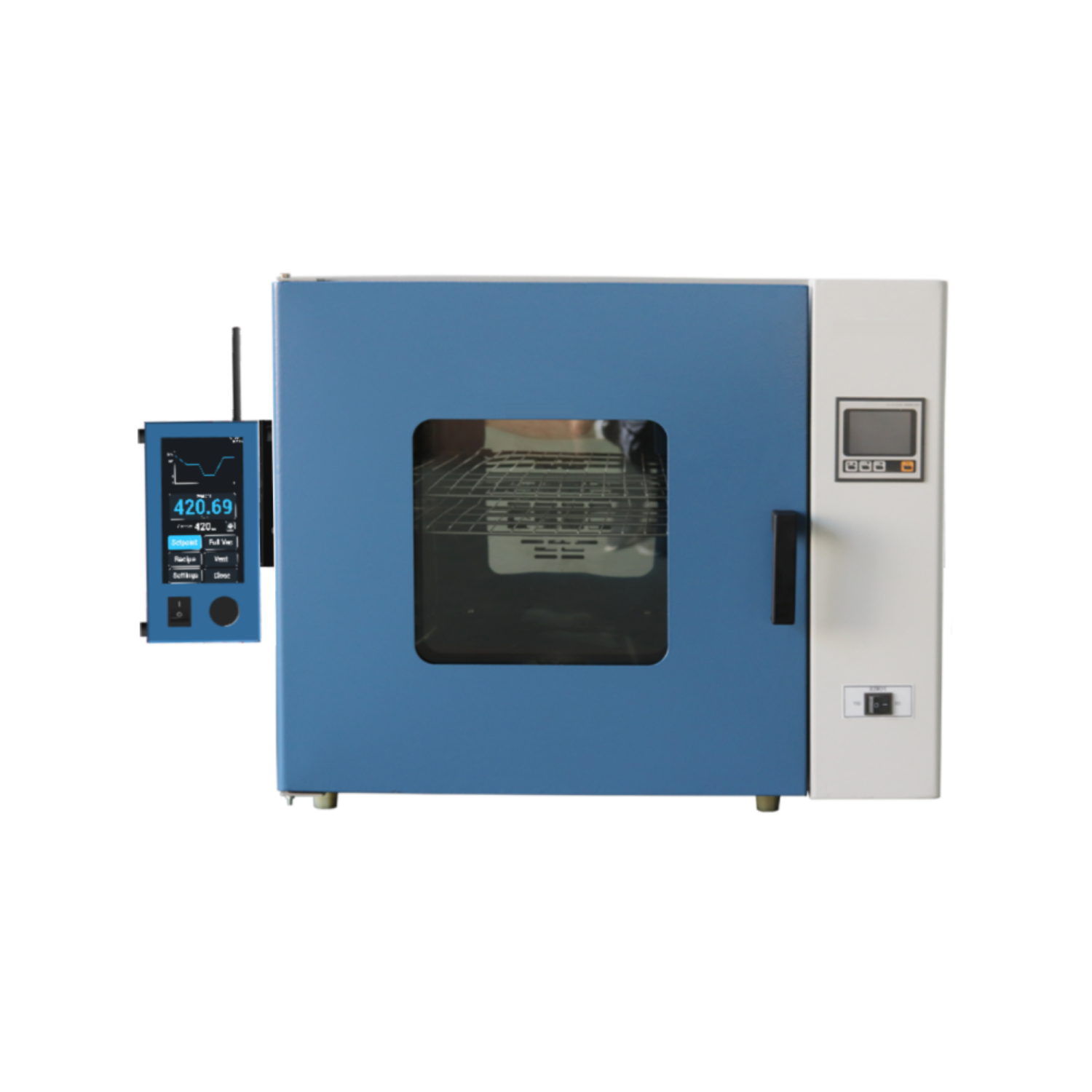

- DigiVac SNAP Controller on an Ai Vacuum Oven

- How to Set Up the DigiVac SNAP Controller to a Vacuum Oven

- Vacuum Drying: Polymers

- SNAP Controller Overview