The Original Resinator’s Behind the Process: Crop-to-Cure® Part 4

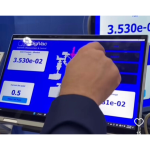

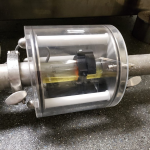

From the newly improved aromatic terpene profile achieved with the digital bleed valve from DigiVac’s StrataVac, The Original Resinator was now able to optimize freeze drying for their botanical products to retain the quality that customers expect, while bringing products to market faster. The research and experiments that went into the parameters for the bleed valve control benefits not only the user, but improves the overall quality of the cannabis.