What Extraction technique is Right for YOU?

The Big Three

The Cannabis Market uses Three Main Extraction Techniques: CO2, Liquefied Hydrocarbons, and Ethanol Extraction. Learn which technique is the best for you as we dive into how each method works, how the extraction takes place, and who would use and why someone would use one specific method over another.

CO2 Extraction

In C02 Extraction the distillate can be isolated easily by reducing the pressure which evaporates the CO2. This Leaves the cannabis extract with no solvent. Tweaking the temperature and pressure affords CO2 systems the ability to yield extracts with a complete terpene profile.

Sophisticated extraction apparatus can also incorporate fractionation, which enables process tuning to isolate desired components. Refrigerated chillers that are integrated into these systems facilitate recycling of the CO2 by condensing the gas back to a liquid state.

Check out our Arometrix Technology! Perfect for in real time Extraction and Molecular Data Analysis during your process!

Liquefied Hydrocarbons

When utilizing the Liquefied Hydrocarbon Technique the systems pressurize butane, propane, or other low molecular weight hydrocarbons to a liquid state. The liquid hydrocarbon passes through a bed of plant material and filter, yielding an extract solution of hydrocarbon and plant extract. Like the CO2 method, a reduction in pressure evaporates the hydrocarbon liquid, yielding a solvent-free plant extract.

This method requires great attention to safety due to the flammability of the hydrocarbon used. Maintaining the pressurized hydrocarbon in the liquid state requires low temperatures. Butane has a low boiling point and is the most common hydrocarbon solvent currently used in extraction. It is favored for its non-polarity, which allows the extractor to capture the desired cannabinoids and terpenes without co-extracting undesirables including chlorophyll and plant metabolites.

Ethanol Extraction

Finally when using Ethanol Extraction as your main method you would see the Systems use food grade or USP grade ethanol as a solvent to extract plant material. Ethanol is the second most important solvent (after water) in consumer products. This method varies from vessels to reactors, filter reactors, spinning vessels to barrels.

Ethanol is a polarized molecule. A polar solvent will readily mix with water and dissolve water soluble molecules. Chlorophyll is one of those compounds which will easily co-extract when using ethanol as a solvent. When a concentrate retains chlorophyll, it introduces a dark coloration and an undesirable bitter, grassy flavor. Activated carbon filters may be used to eliminate impurities.

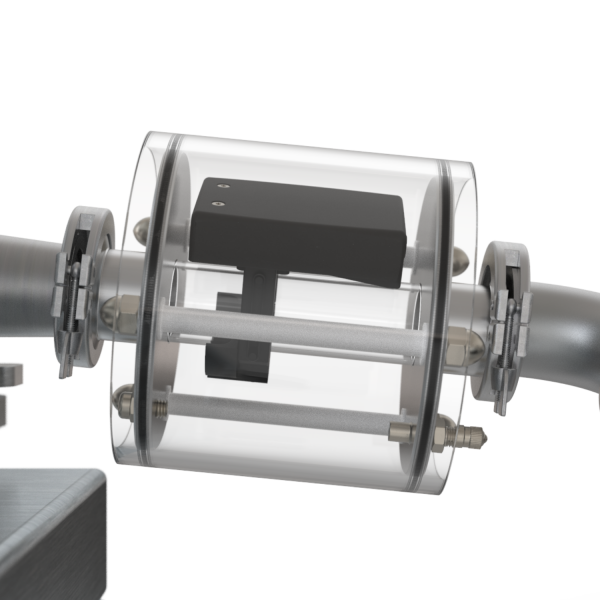

Ethanol extraction can be carried out by several methods including cold, warm, or room-temperature processing. Some ethanol extraction processes involve the use of a rotary evaporator setup to remove the ethanol from the extract solution.

Ethanol extraction is popular for several reasons:

- Can extract a full spectrum of compounds from cannabis plants

- The process can be adjusted to prevent certain compounds from solubilizing

- Generally, equipment costs for ethanol extraction are lower compared to other methods

- Ethanol is the least toxic of the alcohols

- Ethanol can be recovered and recycled

- The resulting ethanol solution is concentrated via vacuum distillation (falling film, reactor, or rotary evaporator)

- The solvent-free, purified extract can be dried on trays in a vacuum oven to yield a yellow to amber extract.

Want more content? check out our YouTube channel here, want to learn more about what our DigiVac tech can do for extraction check out this product here!