What is the Cold Chain and how does Cryo-Trim® play a part in the Crop-to-Cure® Process?

The Original Resinator’s Behind the Process: Crop-to-Cure®

PART 2 | Cyro Trim

The Problem

As we discussed in our previous article “How Do You Optimize Botanical Freeze Drying?”, there is more to the process of freeze drying than just a simple project fix to vacuum engineering. It is a science. And part of the science is what is known as the “cold chain”. The cold chain is the process of actions and equipment required to maintain a product within a low temperature range from harvest to consumption. This means reducing the total time required from garden to shelf by leveraging the lyophilization process during harvest. That is why creating a cost and time efficient way to cure, sublimate, and freeze dry cannabis is a priority for DigiVac and The Original Resinator. From freezing conditions and environmental exposure to live buds, the research behind the Crop-to-Cure® technology was challenging because

The Original Resinator is trying to cut back the time and effort required to achieve the same or greater results in less time compared to traditional drying methods.

Solution:

Sublimation of the moisture in cannabis was part of the research when working with the cold chain procedure because of the additional state of the botanical being frozen. The transition state between ice and gas can be a delicate balance when working with botanicals in vacuums. And as stated before the ideal process was to cut the time during each stage of the process to help customers create efficiencies within their business to ultimately produce a more profitable product. As a result, part of our research when adjusting for the cold chain was to Cryo-Trim®.

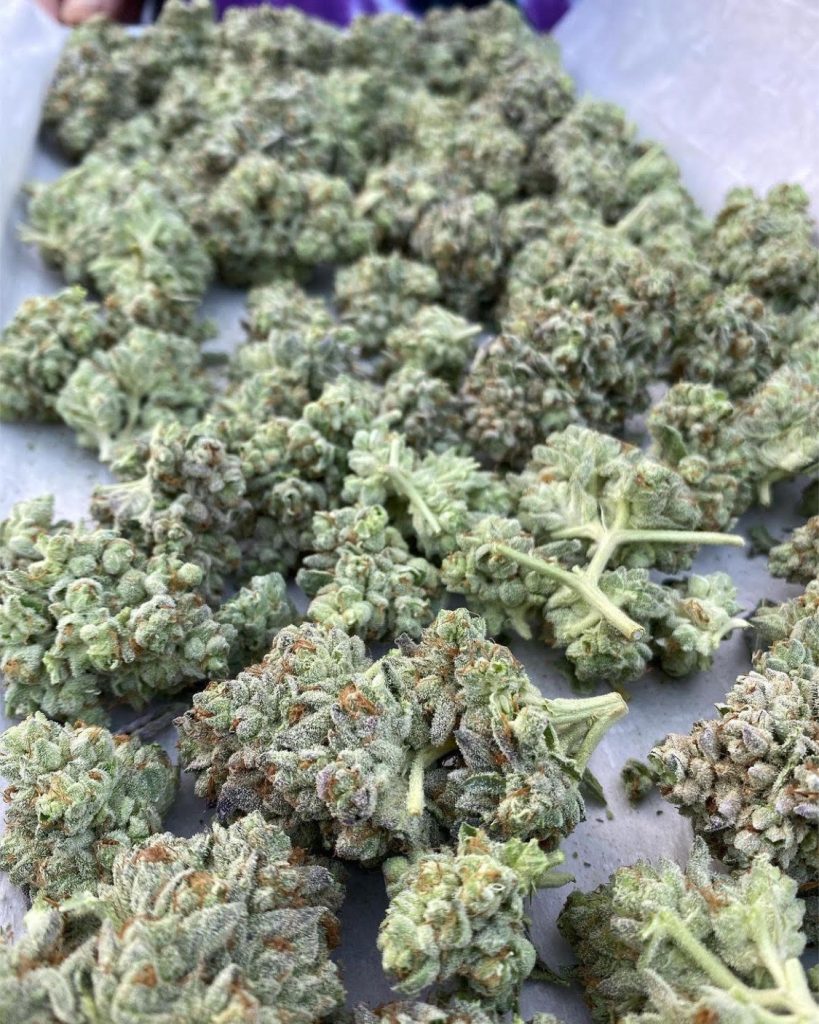

Cryo-Trimming is the microinjection of liquid carbon dioxide into the chamber of an Original Resinator machine to make water and sugar leaves instantly brittle, which allows them to quickly fracture and fall from the buds. By momentarily flash freezing the biomass we are able to produce the cleanest manicure in the shortest amount of time without causing any damage or oxidizing while preserving cannabinoids or terpenes.

By speeding up both the harvesting and curing of cannabis using a lyophilization process, we can perform better engineering with our vacuum to ensure the right pressure, time, and temperature that’s needed to produce the same results.

Check out TOR’s Crop-to-Cure bundle here and learn more about the technology that flash freezes its chamber for dry or live’ bladeless trimming and optimal vacuum pressure for terpene preservation !

Issue:

The second issue with lyophilization processing is the sanitation aspect of botanicals. We are harvesting, curing, and freezing until we finally sublimate cannabis with testing standards becoming increasingly specific in the botanical industry relating to cannabis. As well as maintaining our own high standard production value, regulation and oversight can come into effect in many stages of the process. It is vital to mitigate any cross-contamination from physical laborers, unnecessary exposure, and machinery to make cryo-trimming and freeze-drying indispensable.

Thus, another reason why optimizing the lyophilization process is beneficial for Crop-to-Cure® is to give the customer the high quality results you expect from our product. Knowing it is done under efficient and sanitary research ultimately increases confidence in the final outcome for both producers and customers.

By pairing the DigiVac StrataVac Bleed Vacuum Controller with the CROP-TO-CURE SOLUTION by The Original Resinator productivity was improved.

Learn more about this inside look at TOR’s Behind the Process: Crop-to-Cure in this 4 part blog series! What more info on Crop-to-Cure? Check out their Q&A here!