Applications | How DigiVac Products can Help with Aerospace/Altitude Simulation

Similar to how a majority of people come across items or products that have potentially touched or come into contact with some form of vacuum, people interact with things a plethora of satellites in space have operated or influenced in some way. Examples include using a GPS to get to and from work, making a call to someone in a different country, checking the weather report, or even something as simple as using the Internet. Satellites are an integral part of modern life, whether we realize it or not.

However, to get even a small satellite up into orbit can take years or even decades – and part of that has to do with the rigorous testing, researching, and calculations that goes into it to ensure the safety, functionality, and self-sufficiency of said satellite. To aid in this rigorous testing, there are a handful of DigiVac products that can help with aerospace/altitude simulation.

Aerospace/Altitude Simulation: Why?

All of this testing is necessary because as most people are aware – space is nothing like Earth. In space, beyond the protection of Earth’s atmosphere and magnetic fields, there is nothing to protect the satellite from extreme temperatures, vacuum, and radiation. From the point of launch to when it gets into space, everything down to the materials that make up the satellite need to be tested so that not only will the satellite survive the initial launch, but can stay functional with little to no maintenance.

After all, with a satellite, operators can’t just go up to it and hit a physical reset button for when the satellite stops working. Thus, from the batteries to the transmitters, they all need to pass multiple rounds of testing to ensure it all works.

Aerospace/Altitude Simulation: How?

Various companies and organizations all have different methods, and there are a plethora of parameters and standards that must be met when it comes to testing satellites. One example is testing a satellite in a climate chamber, to analyze how it responds under duress from extreme vacuum, temperature changes, solar radiation, and more.

Individual materials and components aside, some satellites are tested as they’re being built, with the entire unit getting tested rigorously upon build completion – right before it goes into space. This is done to ensure that the entire unit as a whole can survive the travel to space, and then the subsequent time it will spend up there.

This is where some of DigiVac’s technology can be helpful. Specifically our SNAP vacuum controller with an external quantum sensor and our Bullseye DASH vacuum gauge which lend themselves to being able to read deep vacuum.

Aerospace/Altitude Simulation: What?

Typically, whenever we get contacted for any space or aerospace specific solutions, they tend to be custom builds that have to meet various specifications laid out by the client. However, among the variety of products that DigiVac offers, there are two that come to mind for any aerospace testing needs.

The first is the SNAP vacuum controller with an external quantum sensor. The SNAP optimizes vacuum control by automating it, allowing users to have a bit more of a hands-off experience with their process. We’ve also found that those who’ve purchased the SNAP for space applications specifically prefer it for the recipes that can be saved to it – allowing for continuous, repetitive testing. Especially given that the SNAP can save up to 10 recipes with 24 steps per recipe.

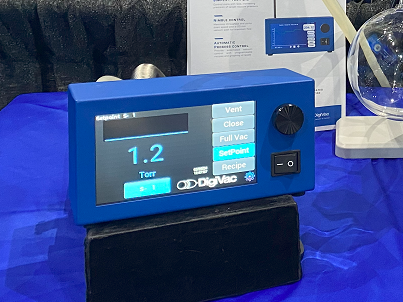

Aside from the SNAP, the Bullseye DASH is a vacuum sensor that can be taken anywhere. Its portability allows for easy validation and checking multiple sensors to confirm the readings. It’s also compatible with a wide range of capacitive manometers, so hooking it up to a system and checking the sensors is an easy task that can be done on the go. Additionally, the DASH can read deep vacuum, ideal for space testing.

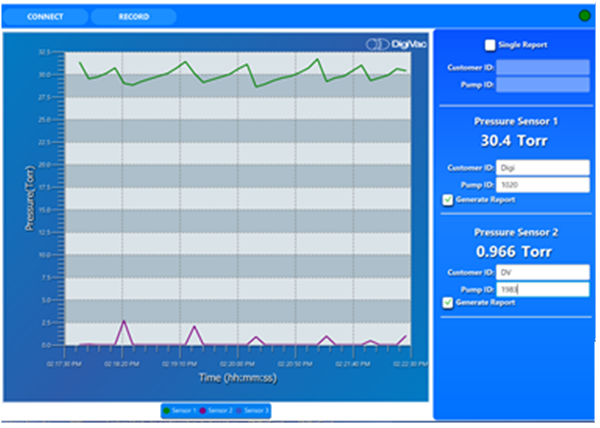

DigiVac also has software that those who do aerospace testing might find useful as well, such as the StrataCapture. StataCapture can record data testing in real time, helping run thermal vacuum tests on materials in a simulation of what they’d be going through while orbiting the earth. By capturing and recording it all, StrataCapture provides easy and accessible readings when needed on testing processes.

Want More Info?

If you want further information or just have any questions/inquiries about any of DigiVac’s products, feel free to browse our website or contact us!