Advantages of Using Capacitance Manometers for Measurements

As technology marches ever forward in the name of progress, it’s always interesting to look at how far some of the scientific equipment we use today has come. One of those devices is the capacitance manometer. The manometer has been improved and iterated on many times over the years.

While there are many different methods for measuring pressure, using a capacitance manometer is often considered one of the most accurate and reliable methods. If you plan on using a capacitance manometer in the near future, or if you’re simply interested in what they do and how they work, we’ve created this article for you. We’ll go over the definition and some of the advantages of using capacitance manometers for measuring pressure so you can see why they are a staple in many different industries.

Capacitance Manometers Defined

So, what is a capacitance manometer? The old-school manometer created long ago was a device that measured pressure by using a column of fluid. This column of fluid was suspended in a U-shaped tube, though there were other shapes as well, and pressure was exerted on either one or both sides of the tube.

Modern capacitance manometers use far more advanced technology than a simple column of fluid. The key to how capacitance manometers work is a small, flexible diaphragm fixed in place between two different electrode plates. These plates create two separate, and completely isolated, spaces that allow us to measure the difference in pressure between them. The flexible diaphragm reacts to pressure on either side and will bow towards one side over the other based on the pressure difference. The way the diaphragm bends will cause an effective capacitance imbalance.

This imbalance gets converted into a voltage that is proportional to the amount of pressure. The capacitance manometer takes that voltage measurement and translates it into a reading that we can understand. The voltage measurement that it produces is a far more accurate measurement of pressure than an old-school manometer could ever produce.

Advantages of Using Capacitance Manometers

Now that you have a better idea of how capacitance manometers work, we can talk about why you choose one over other vacuum measurement methods in your lab. As we’ve mentioned previously, a high degree of accuracy is what makes capacitance manometers so useful. We’ll look a little deeper into the details to show you why you should consider using a capacitance manometer on your vacuum system.

Capacitive Manometer Sensors

The capacitive element of capacitance manometers also known as absolute pressure gauges are mechanically simple and accurate.

Capacitive manometer gauges can operate over a wide temperature range and are very tolerant of short-term overpressure (or above atmosphere) conditions.

Different Manometers can be used to measure a wide range of vacuum pressures and are oftentimes used in a series to cover a wider range of vacuum such at 1000 Torr, 100 Torr, down to .01 Torr. They’re ideal for both lower-pressure applications and reasonably harsh environments. What sets capacitance manometers apart from our vacuum measurement technology is their accuracy. They are rated for accuracy up to 0.1% of the full-scale value and they are gas independent.

Capacitance manometers measure true pressure (defined as force/unit area). This means that the measurement is insensitive to the type of gas being measured. Other gauges, such as Pirani, thermocouple and ion gauges, do not measure true pressure, and therefore their readings will be gas-type sensitive.

Other Advantages

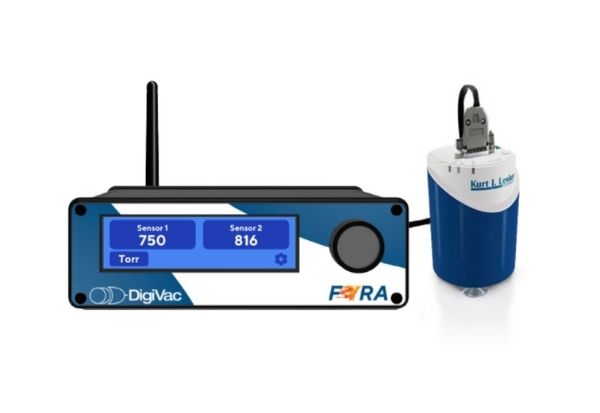

Capacitance manometers also have inherently low power requirements. This is why ambient absolute pressure gauges can be powered by the battery-operated Bullseye DASH. DigiVac gauge controllers power the absolute capacitance manometers, interpret the excitation signals, and digitally display readings on the screen.

Capacitance manometers are usually stand-alone transducers typically requiring a 24V or 15-volt power supply and deliver a 0-10 volt pressure signal that is directly proportional to pressure. DigiVac gauges and controllers take this pressure signal and interpret that signal into a corresponding vacuum reading (Torr, kPa, mbar, etc).

In addition, our controllers have inherent software that will blend different sensors readings so that you can view one reading from several sensors at once. For example, when setting up a standard and require multiple absolute pressure gauges, DigiVac controllers will blend the various readings as the range for one drops off and the next one takes over so that the user is seeing a seamless measurement on the display.

Capacitive manometers exhibit low hysteresis and good repeatability of measurements. They also have low temperature sensitivity and have an extremely fast response time in the order of milliseconds, and even faster in the case of MEMS devices.

The main disadvantage is cost. Capacitance manometers are relatively more expensive than other vacuum measurement technologies, and you may have to buy several to cover a larger range of vacuum. However, for many applications the price of admission is worth the cost to gain the benefits these gauges deliver.

Here at DigiVac, we understand our customers’ needs. We know that you want quality products that deliver accuracy and reliability you need for a particular application. If you need a highly accurate, gas independent vacuum gauge then a capacitance manometer may a good choice for you. At DigiVac we have a technical sales team with decades of experience ready to help you with recommendations that are best for you.