Debunking Vacuum Related Myths in Processing

Tips to avoid common mistakes using rotary evaporators for solvent recovery.

Rotary evaporators are advanced scientific instruments that are commonly used in chemical laboratories, processing laboratories and in research to facilitate fractionation. This separation process allows the solvents to be removed gently through evaporation and the precise control of the temperature. This process is vital for many laboratory applications, and as such has led to their widespread popularity.

This blog focuses on common misconceptions regarding the use of vacuum with a rotary evaporator. Many rotary evaporators on the market, have excellent temperature control but do not come with onboard vacuum control. Let’s dig into some common myths that we have heard from customers about using vacuum regulation with rotary evaporator systems.

“I need as deep a vacuum as possible.“

FALSE!

- Too deep a vacuum can result in the solvent evaporation not being optimized to its boiling point. In chemistry, the vapor pressure and boiling point are inversely proportional to each other. We can say that the boiling point increases as the vapor pressure decreases or vice versa.

- You could end up with uncontrollable boiling and foaming this is sometimes referred to as “bumping”

- The product will escape the evaporation flask resulting in system contamination, possible product loses and having to restart your run…stay tuned for a way that you can quickly and easily stop bumping in your system with the SNAP Vacuum Controller.

“I need to run my pump at full throttle.“

FALSE!

- If the vacuum pressure is too high, the solvent will not have time to condense into the flask

- Which can lead to your vacuum pump being flooded with solvent and possibly damaging the pump, the use of a vacuum controller/regulator will help solve this. Also another fail-safe is to have a cold trap or chiller added to your system to help condense the vapors before they get to your pump.

- This leads to poor solvent recovery since you cannot recover solvent from inside a pump

- Finally, running a vacuum pump above its base pressure for extended periods of time is not good for its longevity.

Adding a vacuum controller to your rotary evaporator system can help you avoid these issues. A precision vacuum controller can help you optimize your solvent recovery process as well as preserve the life of your vacuum pump by providing some isolation between your system and your vacuum pump as well as keeping it running happily nearer to its base pressure.

VACUUM CONTROLLER OPTIONS | RANGE 1 Torr to 760 Torr | Rough Vacuum

DigiVac offers the Vapor Pressure Controller | VPC for Rotary Evaporation applications. The VPC provides innovative yet simple vacuum control for rotary evaporator distillation and isolation of plant oils. It has all stainless steel parts and an isolated sensor to support user friendly cleaning in the event the device gets contaminated with process oils. It is UL/CSA certified.

It delivers precise control of target vapor pressure and is designed to tolerate harsh chemicals. Ideal for benchtop rotary evaporators and up to 20L systems.

The new DigiVac SNAP Controller | Simple, Nimble, Automatic, Process

Single Chamber Vacuum Controller

- Automatic Vacuum Process Controller | precise automated control with programmable recipes and graphing of vacuum levels

- Innovative valve control performs both proportional throttle and bleed vacuum control

- The integrated bleed design allows you to quickly vent to atmosphere to stop bumping during processing, which is ideal for rotary evaporation or vacuum oven control with being able to vent to atmosphere with a push of a button.

- Onboard Recipe Control: The SNAP can have up to 8 individual steps in the recipe screen. Time in any step can be up to 999 minutes in duration. It can ramp or hold | Ramp is working up to the setpoint gradually, hold is just “get there as fast as system allows” and stay.

- All stainless steel flow path and standard with KF25 flange

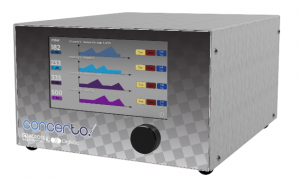

CONCERTO Multi-Chamber Controller By Across International and DigiVac

Vacuum & Pressure Controller that can precisely control Multiple Rotary Evaporators at once (Up to 4) with only one vacuum pump.

- Simplify your lab & control more with Less

- Maximize throughput with a 17.5 mm vacuum path to each hose barb

- Unique Vacuum Control: proprietary dual valve designed by DigiVac offers proportional throttle and proportional bleed control (vent to ATM).

- Each of the four channels have a dedicated valve, Aluminum wetted surfaces

- The integrated bleed design allows you to quickly vent to atmosphere to stop bumping during processing

- Recipes: Program ramps and holds vacuum at different a duration and vacuum level

- Numerical readings right on the LCD screen and one touch start, stop and release buttons

Silver Innovation Award Winner for Instrumentation at PittCon 2020!

The Concerto rotary evaporator controller is particularly useful when you are looking to maintain pressure at a certain level as needed for botanical processing and rotary evaporation.

See overview video here

See how to select recipes here

See how to customize recipes here

See how to easily create set-points here

Bullseye Piezo Rough Vacuum Gauge with Isolated 775i Sensor | UL, CSA, CE Certified

If you are looking for vacuum measurement alone, The Bullseye Precision Gauge Piezo-775i provides highly accurate and reliable vacuum measurement in the rough vacuum range.

- Visual Graphing: Patented digital graphing capabilities (Pump-down graph, Auto-scaling line graph, and bar graph)

- Isolated Sensor: For use in dirty environments or where corrosive gases are in use

- Certifications: CE, CSA, UL, and RoHS

- Measures 1 – 775 Torr (+/- 2 Torr) without a capacitance manometer

- And it is available in a Bluetooth version as well to allow for remote monitoring from your phone or tablet.

Want more content? check out our YouTube channel here!