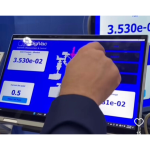

The Dinamo Patent: STEPPER MOTOR PROPORTIONAL CONTROL BELLOWS VALVE

DigiVac just received a groundbreaking patent that commercializes the use of proportional control applied to a vacuum bellows valve. The benefits of this approach to vacuum control are immense. Previously, there were valves that you could control big vessels but were not precise. And there were precise proportional valves but were only good for controlling smaller vessels.