The SNAP Vacuum Controller & Controlling Venting Speed

The Issue

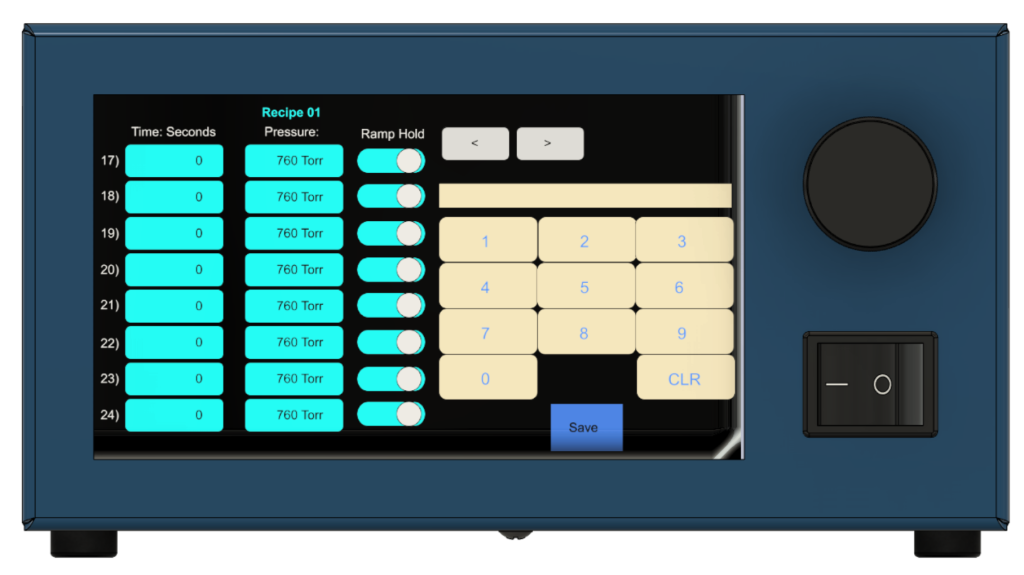

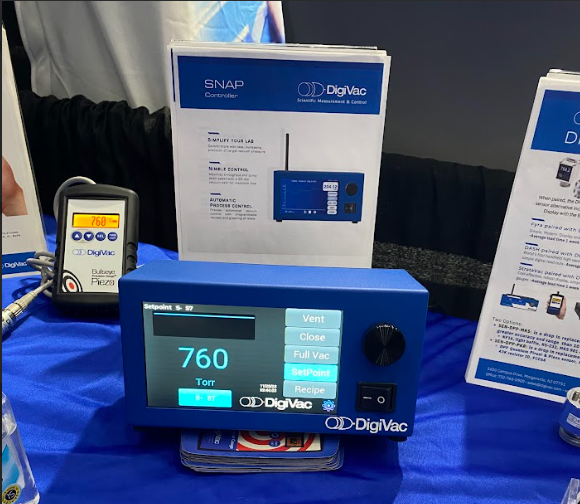

A customer came to DigiVac and expressed the desire to control a vacuum chamber. One specific requirement they had was to be able to vent the chamber in X amount of time. With that in mind, our DigiVac RnD team went to work to take measurements on the venting speed of an off-the-shelf SNAP Vacuum Controller.

Research and Development

For some insight, the SNAP Vacuum Controller has a built-in vent valve that allows users to vent to certain setpoints, as well as vent to atmosphere. Unfortunately, it didn’t vent as fast as the customer desired. That is because the SNAP Vacuum Controller vent valve is a precise device meant to enable controlling within XXX% of a setpoint, not for speedy venting.

Thus, the DigiVac RnD team decided to incorporate a larger, external orifice valve into the control scheme for the SNAP Vacuum Controller. This cut the vent time down to X amount of time.

How controlling the speed of the vent time works is that the external valve utilizes a few variables that are settable through DVCUP.

“VD” is set to a value of any variable between 0 and 100 Torr. The “VDW” variable can then be set to any time between 0 and 100 seconds. That means that if a user is in a situation where the controller is bleeding up to a setpoint, but is unable to achieve that setpoint within “VDW” seconds, then the external valve will open until the pressure is within “VD” Torr of the current setpoint.

Breaking it Down

The Time-Based Vacuum Differential Control is a sophisticated functionality integrated into the SNAP vacuum controller, designed to optimize vacuum control performance by dynamically regulating an external valve based on vacuum differentials (VD) within predefined time intervals (VDW). This feature enhances process efficiency by ensuring that the vacuum level reaches the setpoint within the specified time.

Operational Mechanics

When configured, the Time-Based Vacuum Differential Control continuously monitors the vacuum level against the user-defined setpoint. If the desired vacuum level is not attained within the specified time, the controller triggers the external valve to open. The valve modulation is performed with precision to achieve the desired vacuum level efficiently.

Configuration

Users can access the Time-Based Vacuum Differential Control settings through DVCUP. Configuration involves setting two primary parameters.

- Time Interval (VDW): Define the time interval within which the vacuum should reach the setpoint.

- Vacuum Differential Threshold (VD): Specify the allowable vacuum differential from the setpoint within the defined time.

VDW is defined in seconds, while VD is defined in Torr. If the vacuum level has not increased by at least the VD value by the time the VDW value elapses, the controller triggers the external valve to open.

Example:

VD: 10

VDW: 10

If the vacuum level has not risen by at least 10 Torr within 10 seconds, the controller triggers the external valve to open so the system can vent more quickly to the next setpoint.

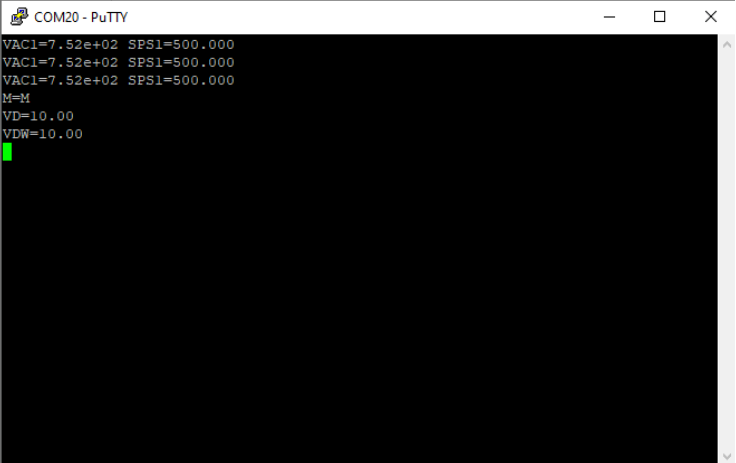

Here is an example of the SNAP connected using DVCUP. The commands for the variables are as follows.

To query the current value:

VD?

VDW?

To assign a new value:

VD=(x) in Torr

VDW=(x) in seconds

DVCUP will not echo the command; it will only display the response.

For More Info

If you want further information or just have any questions/inquiries about any of DigiVac’s products, feel free to browse our website or contact us!