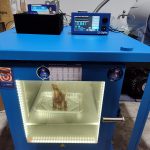

Can Vacuum Drying Expedite Drying Processes?

Vacuum Drying | Can it Expedite Drying Processes? Recently, DigiVac got speaking with some clients about whether the introduction of vacuum could potentially expedite, or speed up, drying processes. Just looking at the method, the answer would seem obvious – especially when put in comparison to simply air drying. However, we wanted to be sure and thus – this experiment was created. Before we begin discussing the experiment, however, some vacuum drying basics should be discussed beforehand. What is Vacuum Drying? Vacuum drying is the “science of removing moisture present in an item or substance through the use of vacuum.”